I bet your king pins are wiped-out. The Sprite Haynes manual encourages you to squirt-in some grease every 3000 miles, but the original Sprite “glovebox” handbook suggests a 1000 mile interval, and I encourage you to follow that guildline. From what we see in the field, it seems like few people do.

Check out the swivel axle in the video below… this car came for a disk brake conversion and upon disassembly, we were surprised to see a nearly seized bushing on this swivel axle, which required major effort just to swivel.

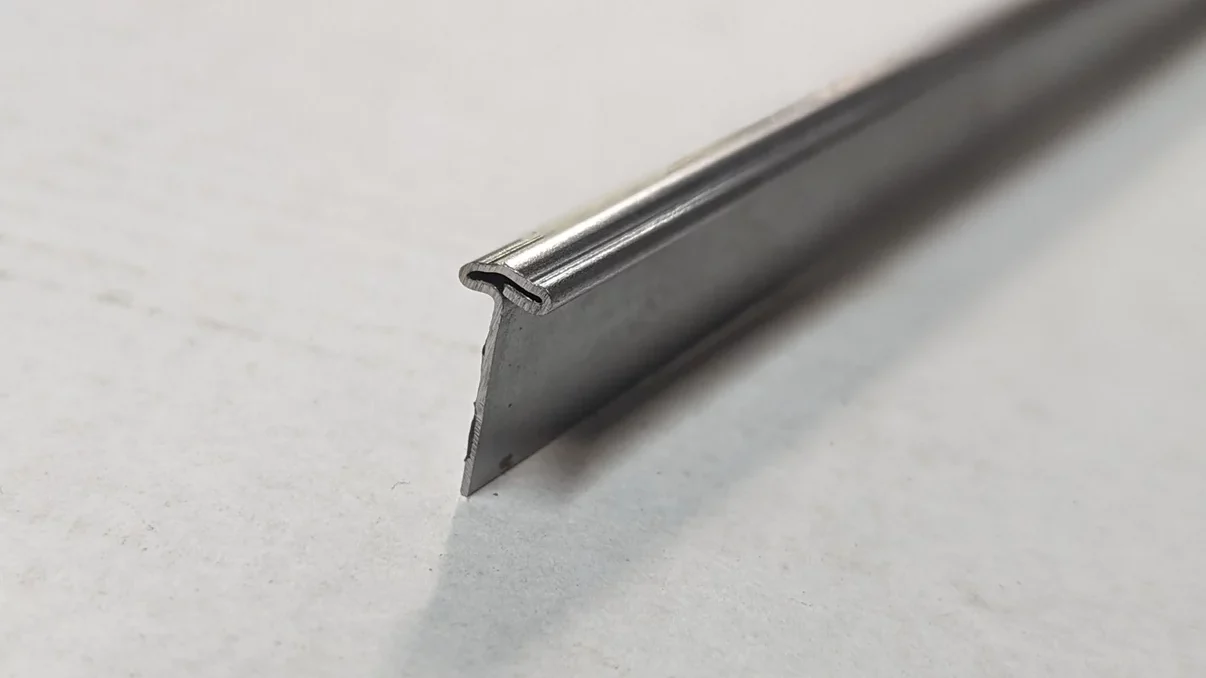

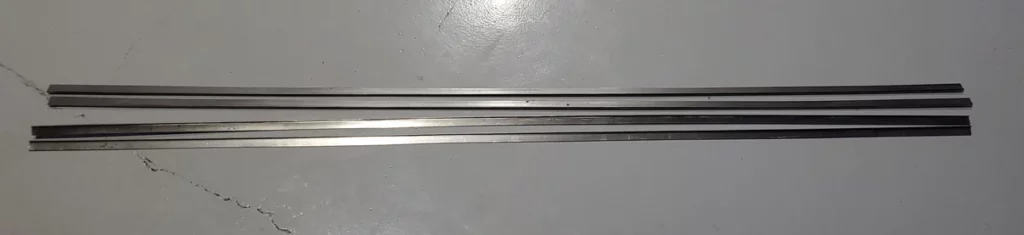

On the back of each front swivel axle are two grease zerk fittings. These two zerks are used to provide lubricating grease to the king pin bushings, two brass bushings that are pressed into the steering knuckle on which the king pin rides. After long periods of driving without replenishing the grease, the bushings can begin to seize to the king pins, creating galling and pitting on the king pins and shortening their service life.

[Read more…] about Feeling bushed