Slave cylinders are perhaps the most common maintenance item on a Bugeye sprites (and on most classic British cars). Of the more than 400 cars we have moved through our building, most have had leaking slaves. As a result, we have changed more than we care to admit, to help keep hydraulic fluid off the ground and to keep Bugeye clutches moving.

The root cause, by the way, is moisture… hydraulic fluid absorbs moisture, and that moisture corrodes the cylinder bores, and then the leaks are soon to follow. Inexpensive slaves made from inferior components and metals seem to corrode faster, with more frequent and pronounced pitting in the bores, and thus they fail faster.

Over the years, we have tried multiple slaves in an effort to find the best one that lasts the longest, and we prefer the slave we offer for sale in our catalog. There are cheaper cylinders available, and it might be tempting to purchase a $20 or $30 slave, but if you value your time you’ll buy the best slave you can and do the job once. Bleeding slaves is never fun, and if you go cheap, you’ll be back under your car again in no time flat, doing the job all over again. Trust me, I have field tested all of them, and the inexpensive ones are just plain junk.

The other thing about changing a slave (whether you do it once or multiple times) is the challenge you face removing the top bolt. Because the frame is so close, you can barely get a wrench on it, and you certainly have limited swing. Thus a lot of the time for this job is spent wrestling with that one fastener.

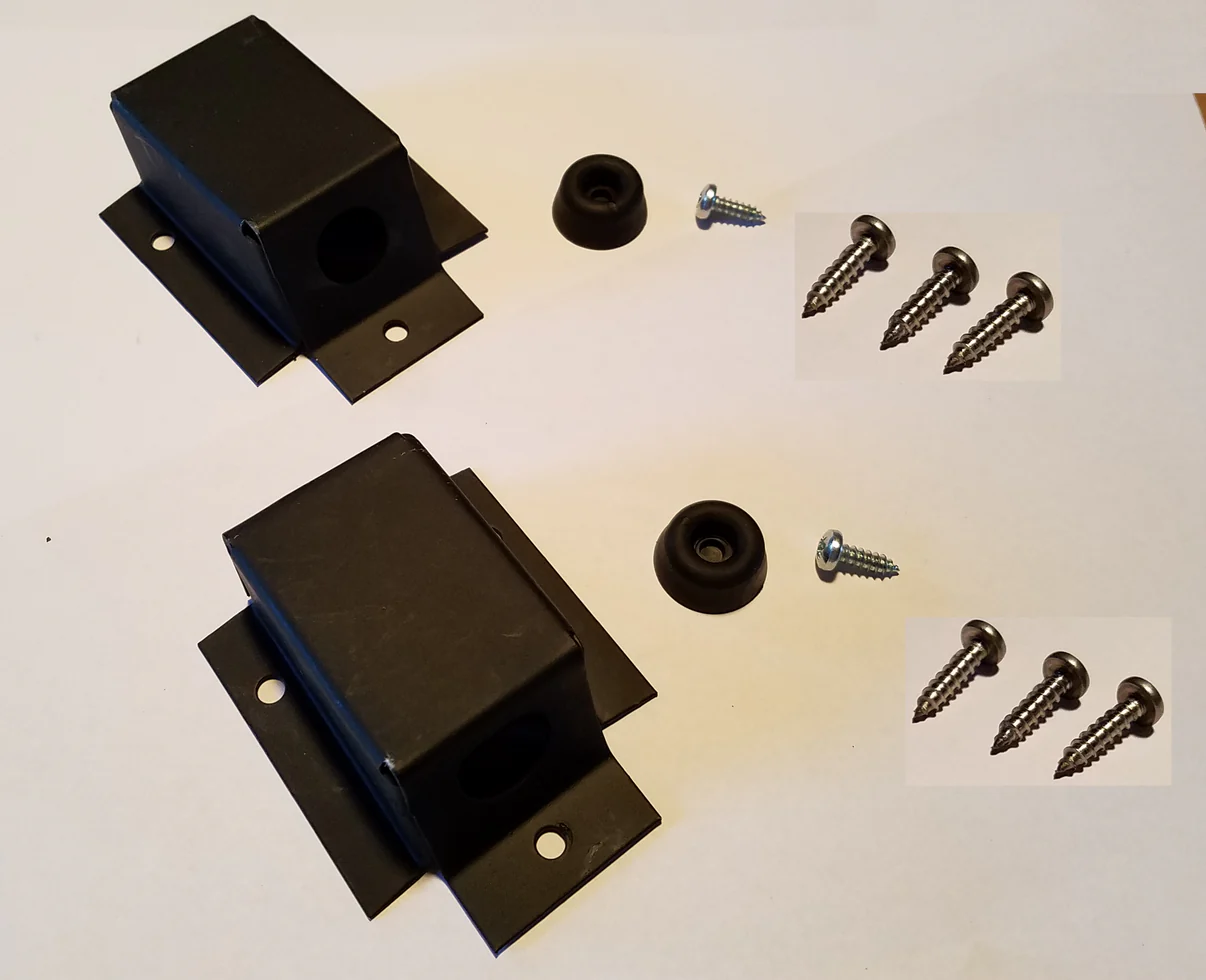

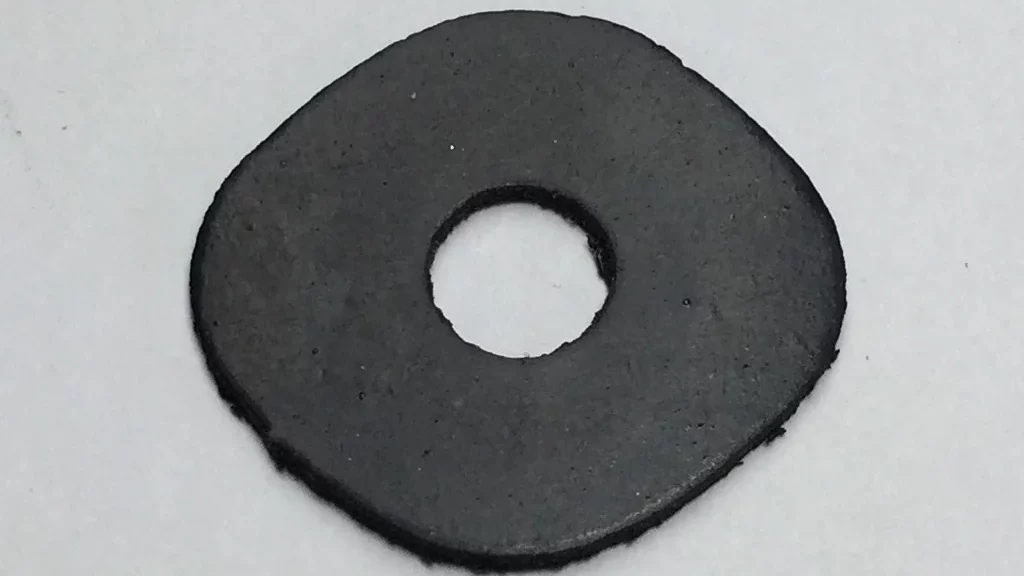

What we do, which you can see in the video above, is a slotted slave system that allows you to save time. This way, you slide the slave under the top bolt without needing to completely remove that time consuming bolt. This is a Bugeyeguys exclusive that makes the install and removal of your slave that much easier. And if you have any reservation about the strength of this item, we have field tested dozens and they work great!

This is a premier European-built slave, the best we have found to date, modified to enhance for your install experience. If your cheap one hasn’t failed yet, it will soon! Get one today by clicking the photo above or by clicking here! And don’t forget to change your hydraulic fluid annually, to get the moisture out.

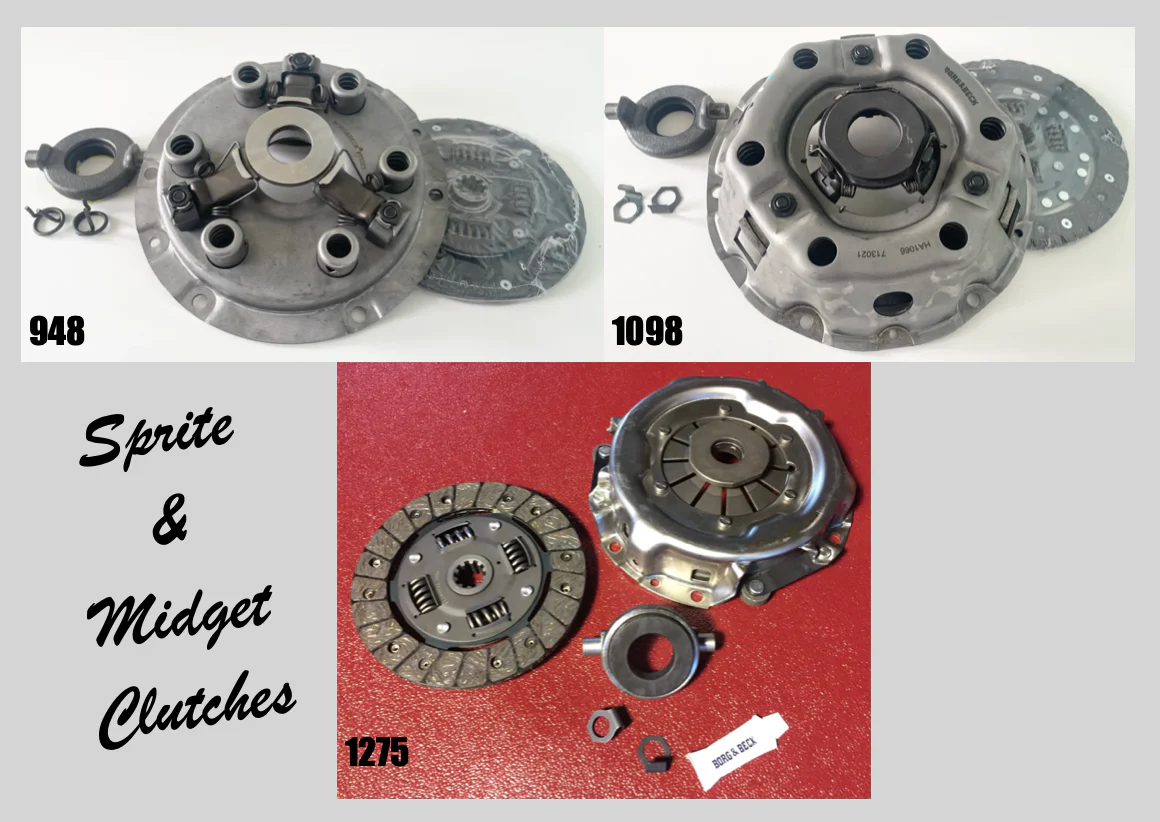

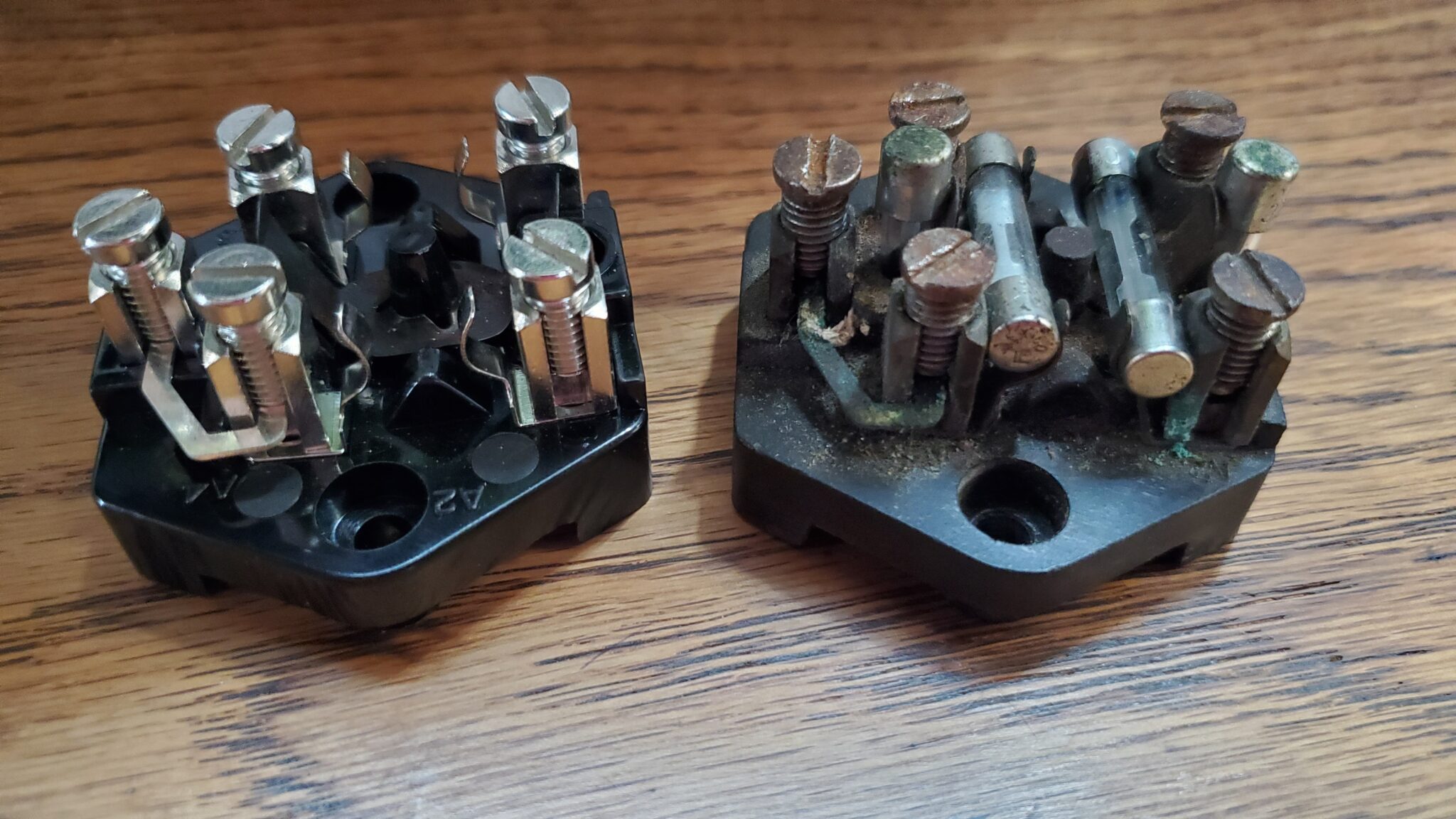

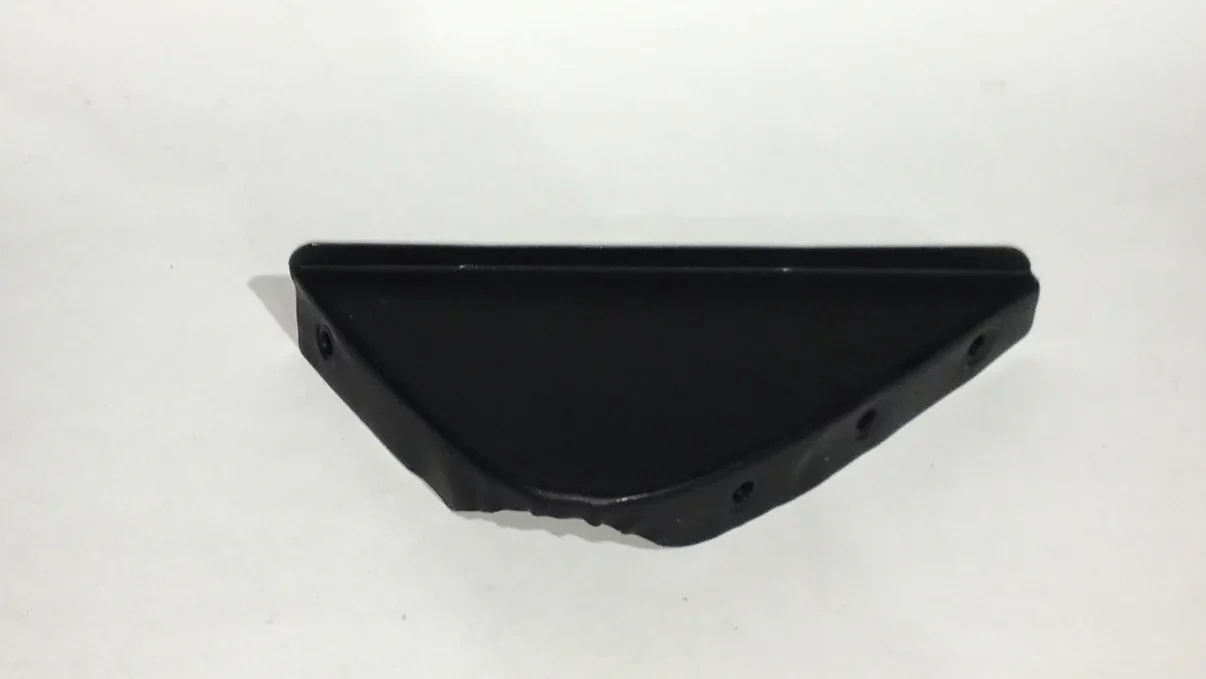

Click the photos below for other important components in your clutch system, or click here for the complete catalog!