This week, we have this Square Sprite here for service that needed lever shocks (which were blown). Upon disassembly, we found a captive nut in the body of the car used to secure the shock to the chassis had stripped.

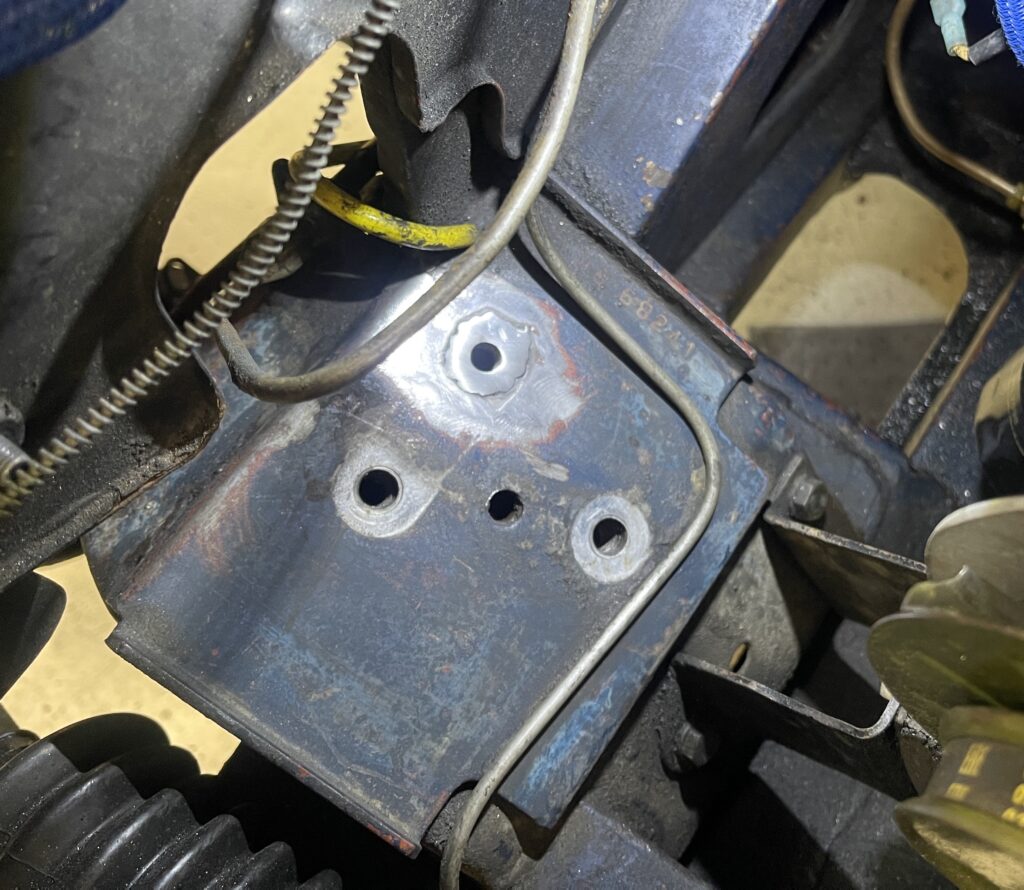

If you’re unfamiliar, there are three bolts that hold each shock absorber to the frame. The front shocks also serve as the upper control arm for the front suspension, so it’s unsafe if only two of the bolts are functional. In order to repair this, we started by cutting out a larger circle of the shock perch and making a threaded insert, using the old stripped captive nut as a guide. We welded the threaded plug into the frame to provide new threads for the shock bolt. You can see that unfolding in the pictures in this post.

If you’re reading this and you own any Spridget (or any Big Healey for that matter), it would be smart to go and check the bolts on your front shocks. They do sometimes loosen-up. They should be torqued to 30 ft. lbs. of torque.

It’s also imperative if you’re changing your shocks that you check the threads in the body of the car. I would put a dab of grease on the threads when you put the bolts back in, just to keep things healthy. These threads are vital and you need to make sure they don’t get damaged, otherwise this complicated repair featured here will be required on your car, too.

We change lever shocks far too often. They’re all rebuilt now, and many of them have been rebuilt perhaps too many times, so they’re starting to fail with increased frequency. We love the front tube shock conversion we sell in our catalog, which you can check out by clicking the photo below. If you choose to invest in the front tube shock system, while they won’t last forever, they’ll certainly far outlive any rebuilt lever shock on the market!