Stuck float bowl needles can stop your car from starting.

A carburetor fuel bowl works a lot like a toilet. As the fuel level in the bowl lowers, a float needle lowers along with it, allowing fuel to flow in from the fuel line and fill it back up as the carburetor uses it. Once the fuel level is full, the needle is pushed up into a tapered seat, where it will rest until it needs to allow fuel back in.

While not a problem inherent to storage of your Bugeye, long periods of rest can certainly contribute to a stuck float needle or two. What generally happens is a small amount of “gunk” gets on the tip of the float needle (the source of this gunk is unclear but a lot of people connect it to ethanol in today’s fuels) and makes the tip sticky, which makes it hang up in its seat.

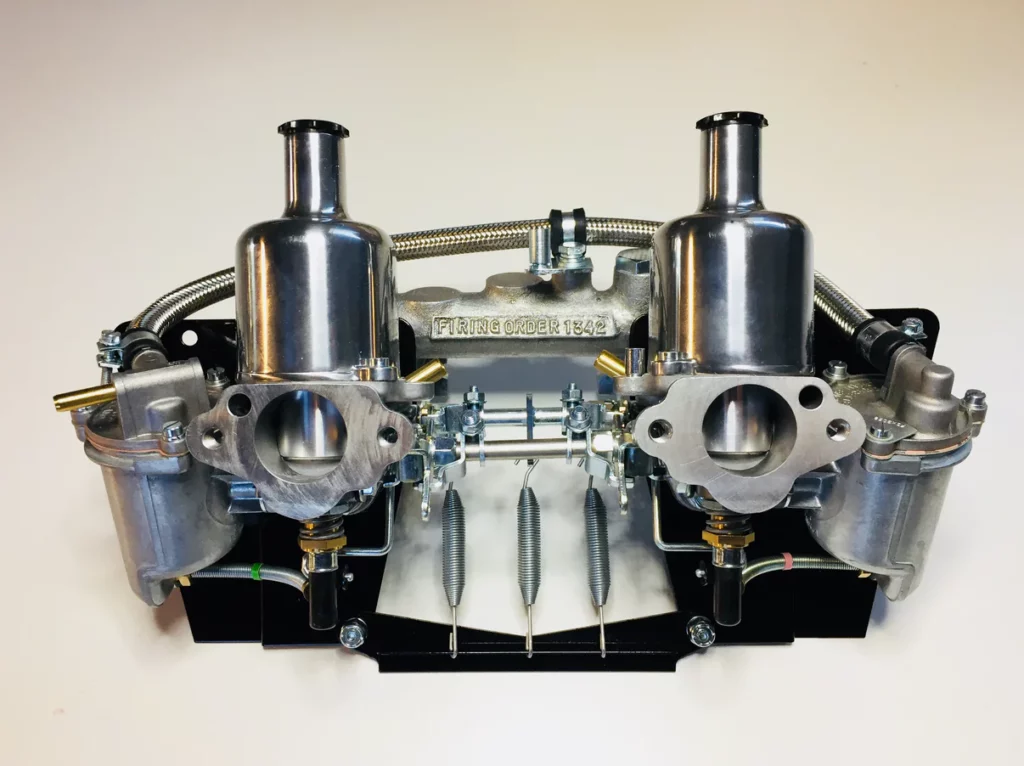

This means that when the fuel level in the bowl lowers, the float also lowers like normal, but the needle doesn’t allow fuel to replenish in the bowl, starving the carburetor. This can cause a condition where the car is running on only two cylinders, or, if both float needles are stuck, can make the car stop running altogether. Check out the video below for an explanation of this issue and some other issues you may encounter with the float bowls on your SU carburetors:

If you find yourself in a situation where you believe you may have a sticky float needle, there’s a simple way to unstick them. Simply take the wooden handle of a hammer (or the rubber-coated end of a screwdriver) and gently tap the side of the float bowl, like we show in the video. This should allow the needle to drop back down and the fuel can flow!

We sell new float needle and seat sets with an improved Viton tip (you can buy one by clicking here), which hold up longer than the original all-metal needles and are also less likely to stick. Additionally, metal-tipped needles can have a groove worn into them over time and are more succeptible to debris in the fuel system preventing them from sealing, leading to the opposite problem, leaking and overflowing float bowls. The video below illustrates this:

Another issue that can cause an overflowing float bowl is what is referred to as a “sunken float”. Over time, the original plastic floats in HS2 carburetors (or the brazed seams on original H1 brass floats) can actually deteriorate and fill with fuel, which makes them too heavy to function properly. This creates a situation where the float sinks to the bottom of the bowl, meaning the needle can’t operate, and causing a situation where the bowl will overflow. In the photo below, you can see by shining light through the plastic float that fuel has entered the float and rendered it uesless.

We sell new HS2 nitrile floats made of material impervious to ethanol, which will prevent a sunken float in the future. We also sell new H1 brass floats should your original also be bad. Click on the photos below to order the carburetor parts you need today, or click here for our full catalog!