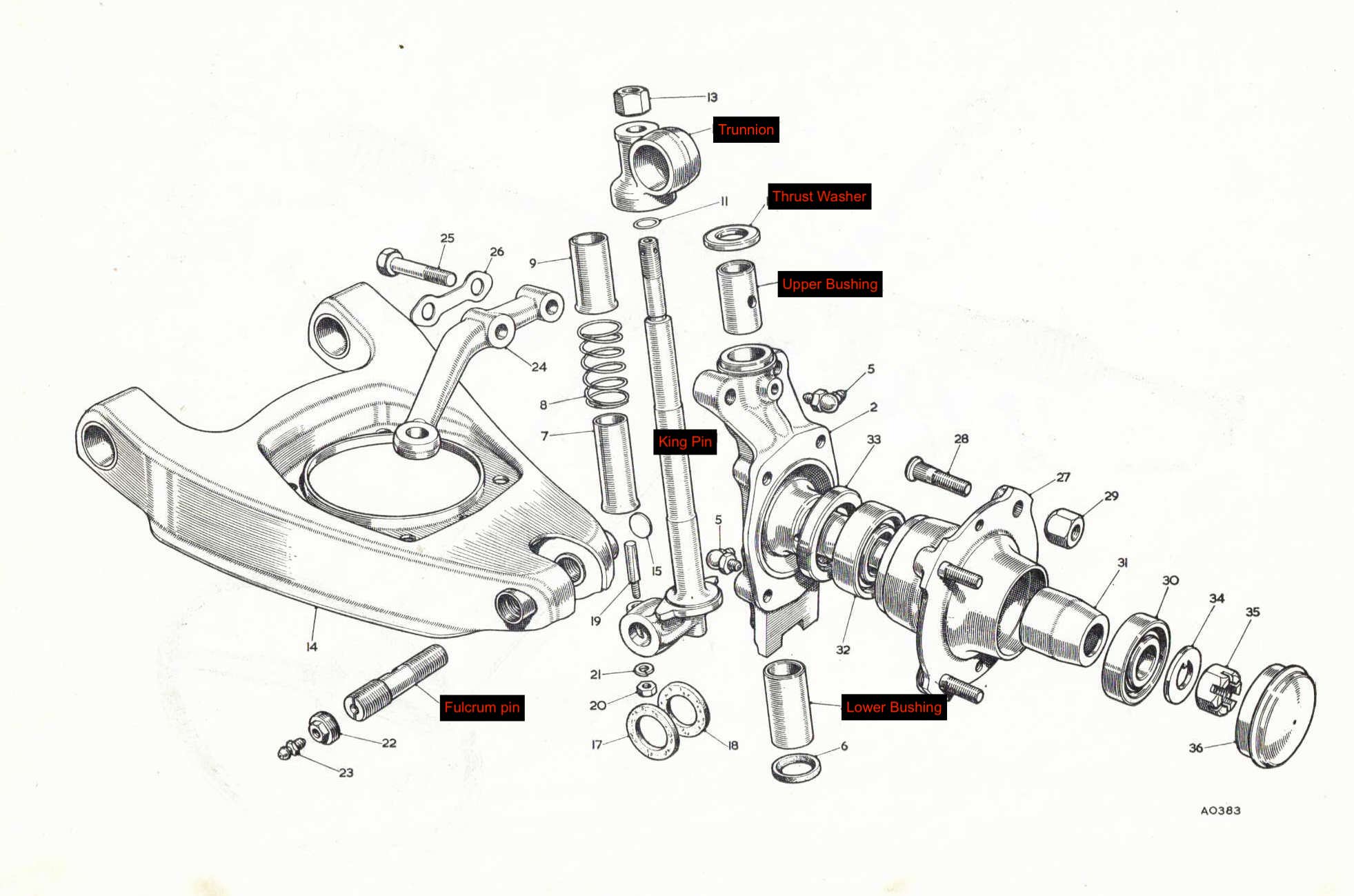

Most Spridget front suspensions have excess play (they’ve had a hard life). Tightening things up pays immediate dividends, both in performance and sure-footedness. Spridgets (and lots of other cars of the era) ride on a solid king pin. The swivel axle that rides on the king pin has bronze bushings pressed in place, and those bushings are prone to wear, especially if they are not greased regularly, as the pair of videos in this post can attest.

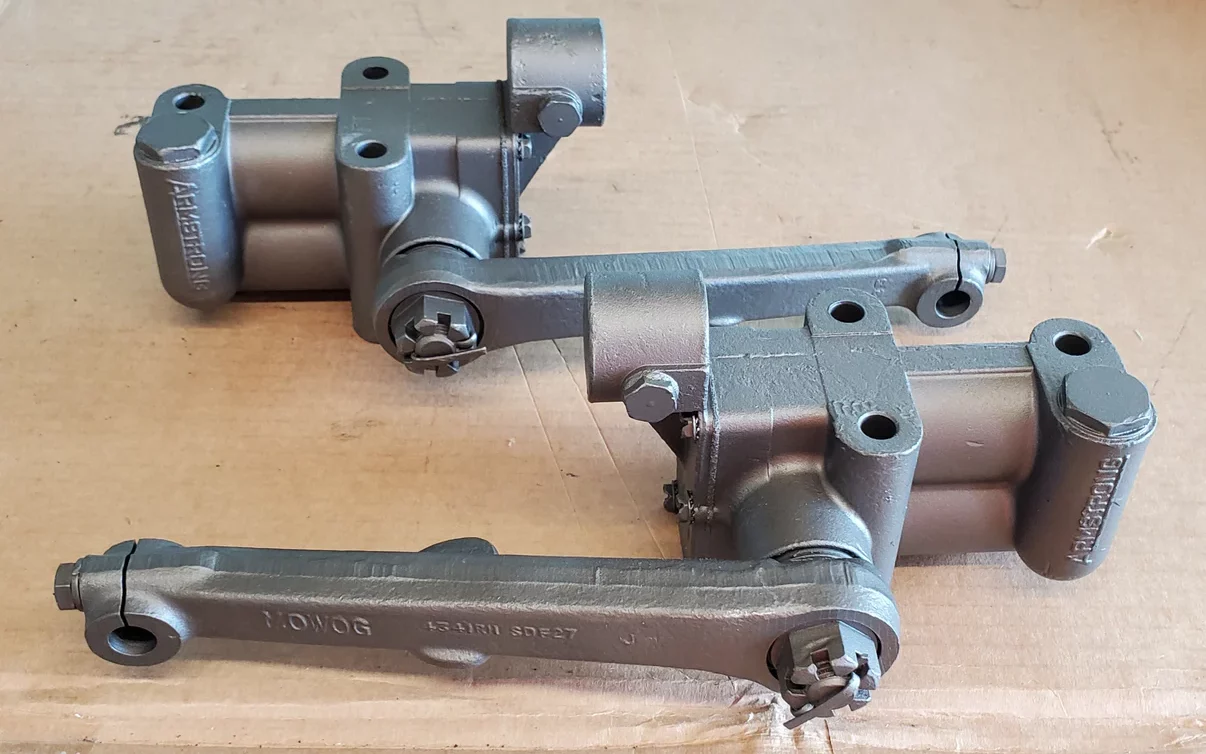

King pin suspension systems have a lot of parts, many more than a ball joint system does. That means many more opportunities for wear, and for part failures. The threads on the fulcrum pin, constantly turning in the control arm as the car goes over bumps, hills, and around curves, wear out, creating slop in the control arm. The repeated vertical motion wears the thrust washer, creating up-and-down slop. Years of constant contact with the road and turning wears the upper and lower bushings, creating lateral slop. The lever shock, which also serves as the upper control arm on Bugeyes, wears internally, creating a harsh ride and affecting the suspension geometry.

So how do you know if your Bugeye has worn king pin parts?

Jack up your car and grab the tire at 6 and 12o’clock, and rock the tire… if you feel play in and out with your bottom hand, your lower king pin bushings might be worn. Try moving the tire at 9 and 3 o’clock… that hand position will help you to see if the wheel bearing is loose… or the tie rod end… have someone else rock the tire and watch from behind so you can observe what is moving and isolate any slop.

One way to tighten things up would be to purchase a suspension major kit for your front end, which includes the components necessary to rebuild your entire front suspension. If you would like to attempt this, we sell the drum brake major rebuild kit here. However, rebuilding a king pin front suspension is a big undertaking, requiring special tools to properly install and ream the bushings in the swivel axle. Even with the correct stepped reamer, this is a difficult job.

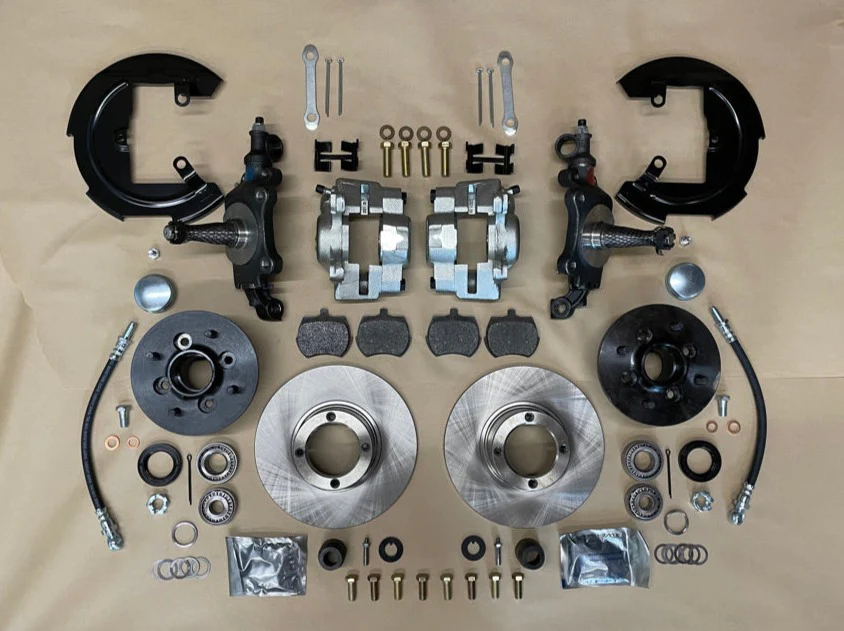

If your drum brake equipped front end is worn, a better plan is to purchase a complete front end kit for a disk brake conversion, because that kit includes new king pins and swivel axles pre installed and properly reamed to the right size.

Our disc brake conversion kit gives you self-adjusting brakes, no brake fade, more consistent braking performance, easier service, better brake longevity, tapered (better) wheel bearings and new properly reamed bushings… a tight front end and lots of benefits!

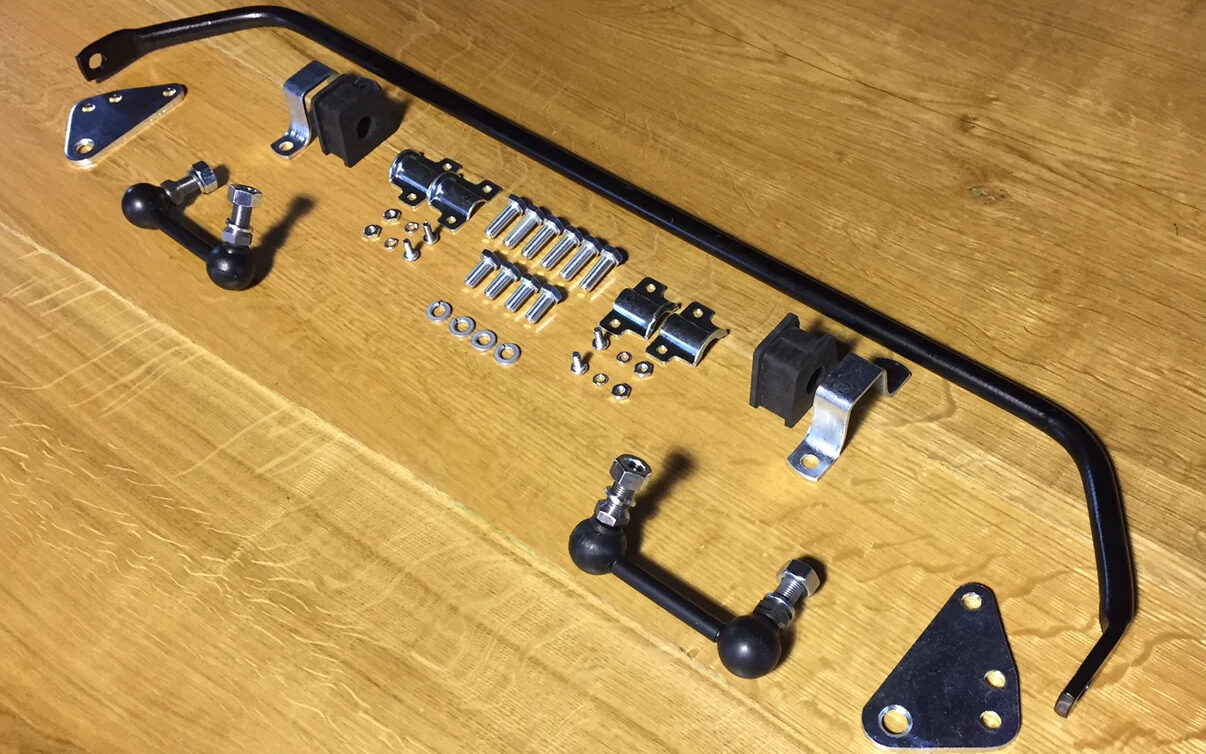

Our kits allow you to remove all of the old components in your Bugeye’s front suspension and bolt-on all brand-new parts, ensuring your Bugeye’s front suspension performs at its best for years to come. Click here to order a disc brake kit, or click the photos below for some more great add-ons that your suspension restoration project will need!