Bugeye tachometers (and their drivelines) often break. (So does any mechanically driven tachometer on any old British car). This continues to be one of the more annoying recurring problems that we end up having to sort. This week, we had a failure in the field from one of our customers and I thought we would use this as a teaching opportunity so that we can all try to make these kooky systems work more effectively in the future.

We haven’t seen this car (just photos), but there are a number of causes that could be at play here, because you have a chain of springs and sprockets trying to translate information from the generator all the way to the tachometer, and if any piece in that chain is not up to code, you can have a failure such as what you see pictured here. This particular tach drive exploded (which doesn’t happen often) but we have a few thoughts as to why this occurred. Note that it was operational in the field for almost eight months (since October of 2022) and had about 200 miles before it exploded.

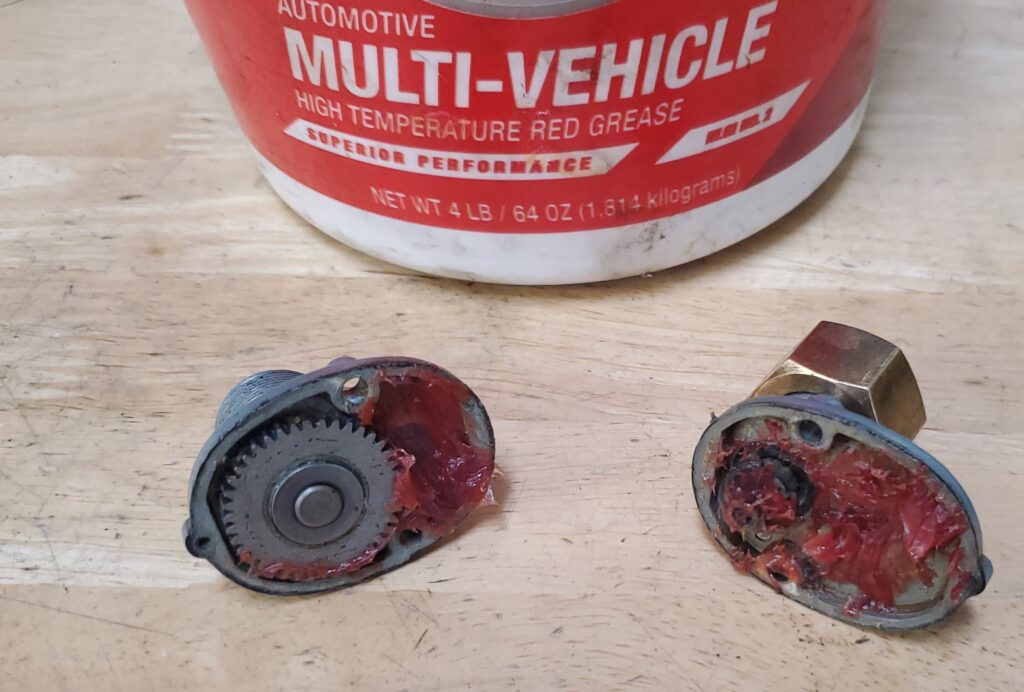

The first thing that can fail is the tach drive itself. Often these are not well-lubricated, especially if it is an older unit that has been installed for a long time. It’s a good idea to take yours apart and fill it with red grease. It’s very easy to do; most tach drive gearboxes (except for early cars) have two small fasteners holding the two halves of the box together, and separate easily so you can pack the box with grease. This should be a part of your routine maintenance schedule. It’s recommended that you should do this once every five years or so. But I don’t think that’s related to why this particular drive failed, as it was a brand new gearbox that was only about eight months old.

The bigger issue seems to be with the interface between the cable and drive . You need to make sure that the cable doesn’t protrude too deeply into the tach gear box because when you tighten the knurled ring, you’ll be putting great deal of force on that inner Cable.

This force can bend the cable end and cause it to make a concentric arc with each revolution, which adds stress to the system; if the NTSB was at the scene of this failure, I would guess their findings would suggest an overtightened knurled ring on a cable the protruded too far into the tach drive. We suspect over tightening because we see a damage on the knurled ring, perhaps from (over) tightening with large channel pliers.

It’s also important to inspect the interface between the tach drive and the generator. We also need to make sure that this junction does not protrude excessively into the generator, and also that the two units mate neatly. Sometimes you need a spacer to support the tach drive in the generator, so it’s worth looking at this mating point.

In the case of this particular tach drive explosion, you can also see a nick on the brass nut, indicating that it was also tightened aggressively, perhaps too aggressively. That can become a problem when there is a void between the tach drive inner spindle and the end of the tach drive inside the generator. Here’s where it’s sometimes helpful to add a spacer, to support the tach drive more effectively.

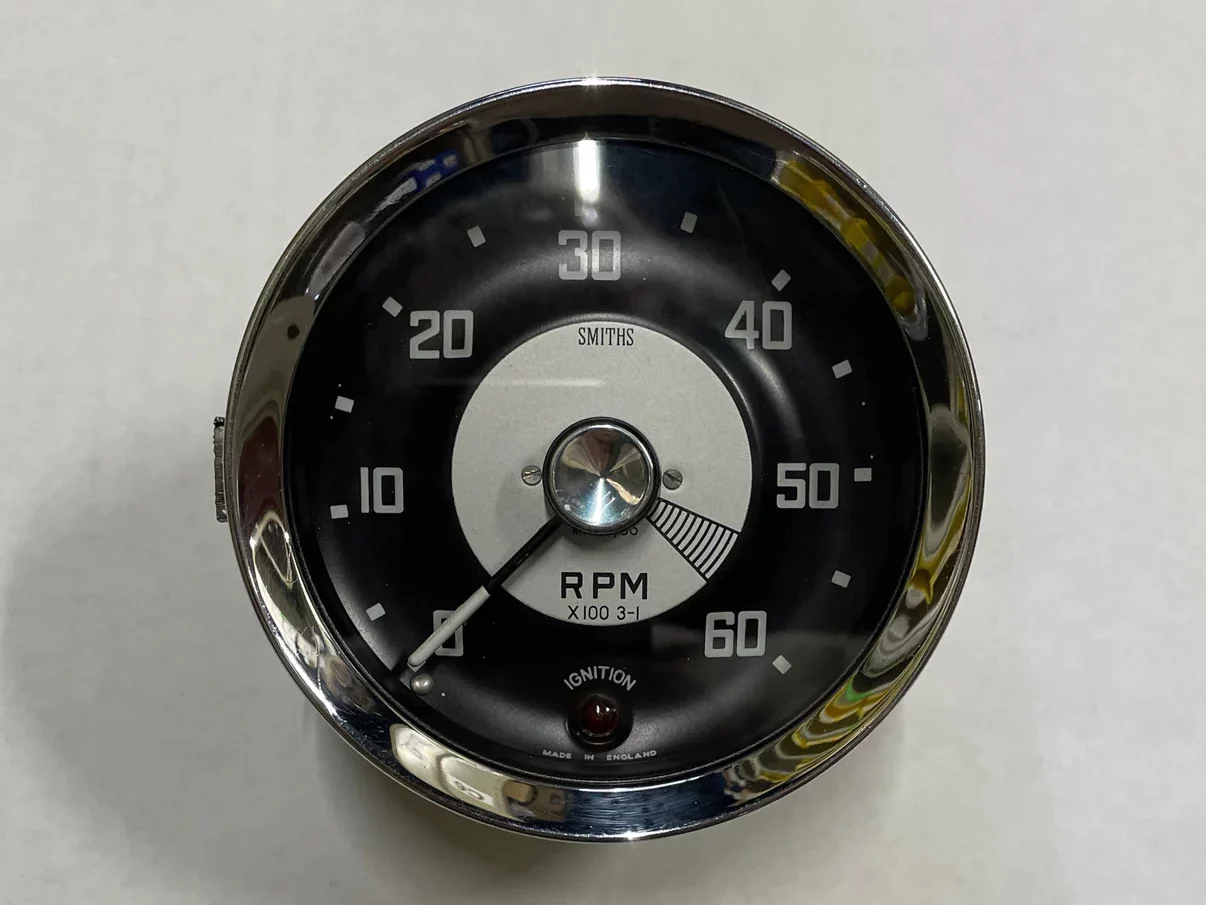

One other important issue is that the tachometer itself can get gummed up. When this occurs, more torque is required in order to drive their mechanism effectively. If that’s the case, it will stress the cable that is unable to turn the gummy tachometer, and this too can contribute to undue stress on the system, which could lead to an explosion of a tach drive, but more often will lead to the failure of a tach cable. So it’s best to remove your tachometer from the dashboard and actuator to see if it is excessively stiff; you can use the end of an old tachometer cable mounted in a drill to check this. Spin it counterclockwise to see if the gauge is gummy or binding. It might be easier to do this with your fingertips with the nipple rather than to use a drill where you can’t actually feel if the gauge is extra stiff.

So when diagnosing a non-functioning, poorly-functioning, or exploded tachometer circuit, it’s helpful to understand the system as a whole. Of course, we offer electronic tachometers should you want to eliminate the mechanical link altogether, or if you prefer, you can send us your gummed-up old tachometer to be rebuilt, a service we are happy to provide for you! Call or email for details.

Click the photos below to get the tachometer components you need to get your rev counter back up and running, or click here for our complete catalog!