We love just about every British sportscar that was built from 1955-1967 (and we’re easily seduced by earlier and later cars too). But given that we are so stuck in the past, we see more systems aging out with each passing year. None of our bits are getting any younger.

This week, brake lines were in focus while working on a car that had been sitting for the past 20 or so years (like a lot of our favorite sportscars). And when the steel brake lines in this particular car fractured the minute we removed them from the vehicle, we had a chance to reflect anew on the (often) fragile fluid link between master cylinder and wheel.

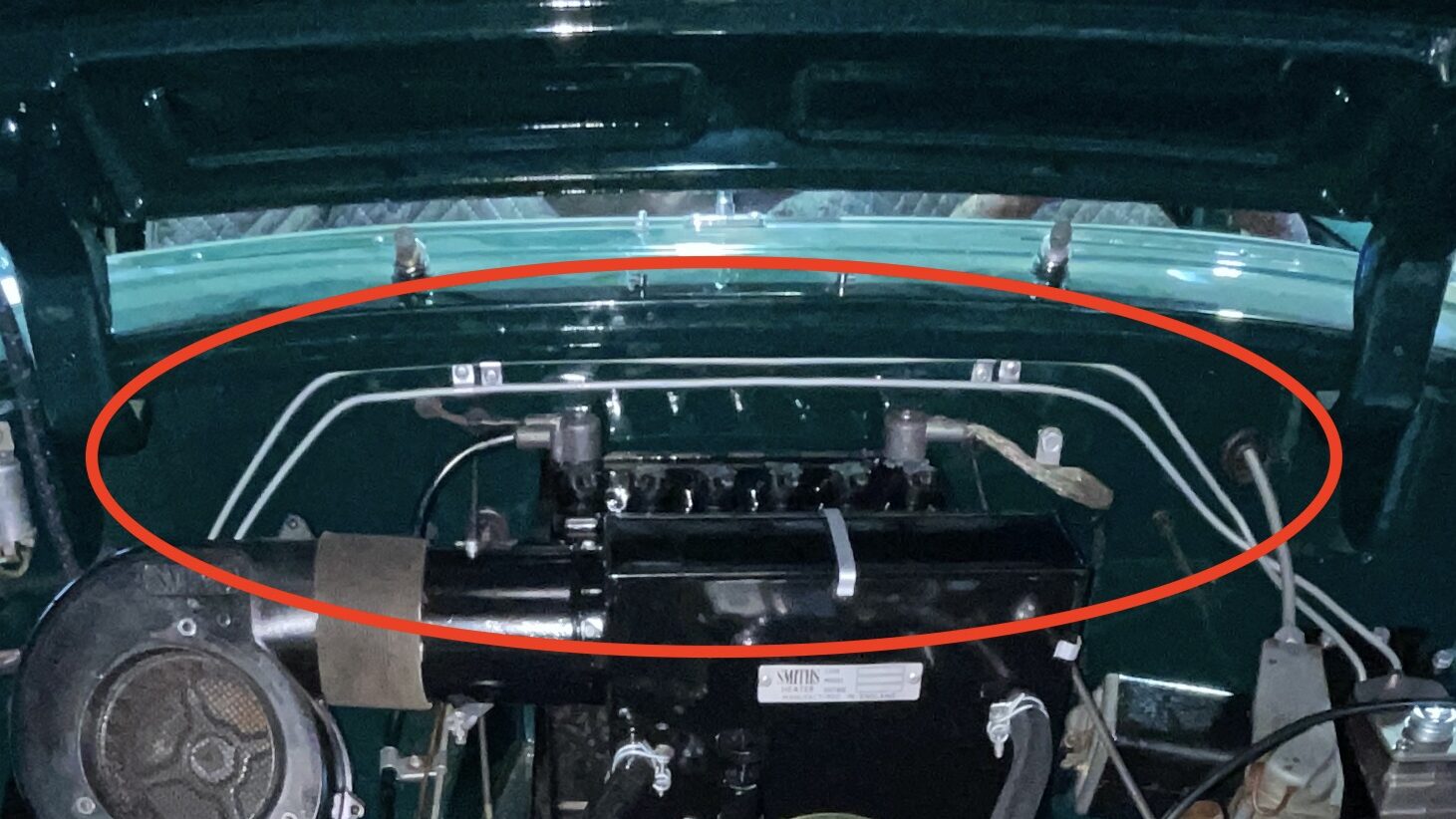

The lines above broke at the nipples without persuasion. These are the original lines, and you can see deep pits and thin walls at the location of the fracture. We have talked previously about moisture in the master cylinder… it not only attacks the cylinder bores, but can damage the steel brake lines as well.

It is critical to make sure your brake lines are in tip-top shape. Thus, more and more, we are changing all of the hard steel brake lines on the Bugeyes that are coming into our shop. Given that the original steel lines are now almost 65 years old, and have been suffering from moisture and corrosion for a very long time, this has become the norm. As such, we recommend that you do the same to your Bugeye, if you haven’t already.

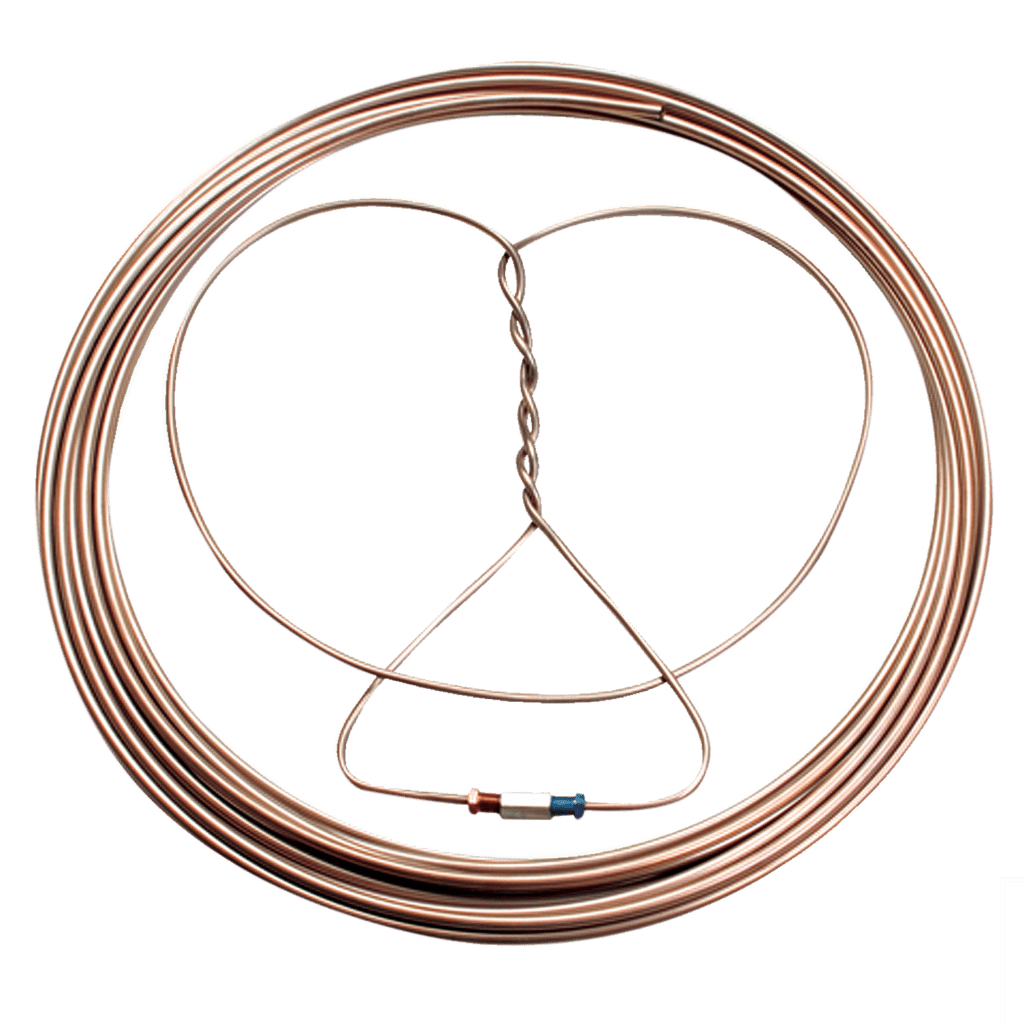

Steel used to be the only material used to build brake lines; stainless steel was at one time a trendy option for corrosion resistance and this material is still used today. However, stainless steel is incredibly difficult to flare and bend.

Cupro-Nickel lines are the answer… this is an alloy comprised of about 88% Copper and 12% Nickel that creates a hydraulic line that is more burst-resistant than steel (unlike pure copper lines, which don’t withstand the pressure of a brake system), has superior corrosion resistance to that of stainless (the stainless coating on brake lines can wear over time), and is softer than any other material used for hydraulic lines, making it easier to bend into the proper shape, easier to flare, and creates a tighter seal than steel. They really are unbeatable and should be used whenever possible on any car that needs brake lines.

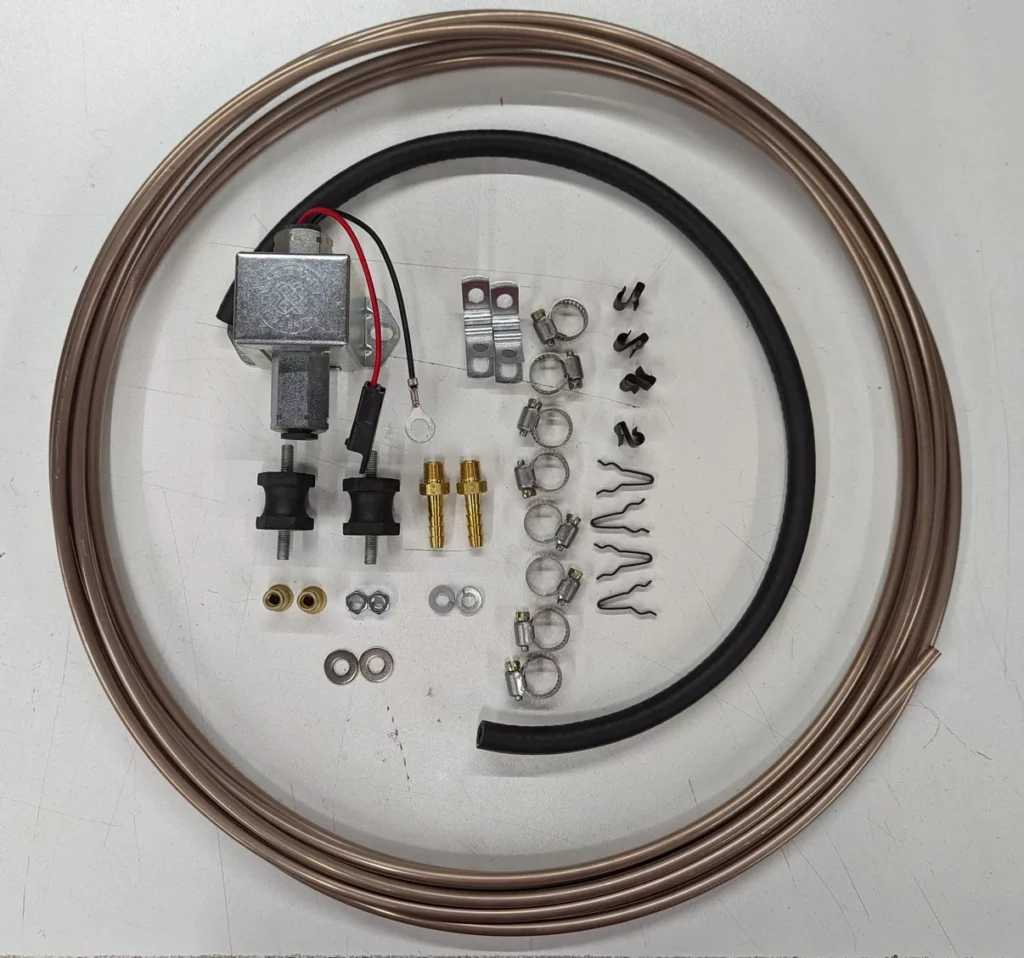

We offer this full kit as well as the hard clutch line and fuel line kits in cupronickel, for ease of installation and superior corrosion resistance. You may never have to worry about hydraulic or fuel lines again!

Click the photos below to order your lines today, or click here for our full parts catalog!