It’s crunch time here at Bugeyeguys! We have been spending our last week before the National Austin-Healey Club Enclave appearance ironing out the final details to get AN5L 501 ready to judge. This past weekend, we had a couple of unbiased third party observers mock judge car 501 and tell us some areas they thought we could improve. (More on that here.) However, there was one area that has been a real point of contention (and sometimes confusion) between the mock judges, our lead project mechanic Terry, our lead project researcher Nick, and myself. That area was the carburetor bowl vents.

As you can see in the photograph above, most of the early Sprites (prior to engine 28913) were equipped with all-steel overflow lines that ran to the back of the engine and terminated around the bell housing. This allowed excess fuel from the bowl to harmlessly make its way to the ground away from the engine bay. Cars after 28913 had shorter steel lines with nylon tubes attached that were a safer (and more cost-effective) solution. However, the standards have a little caveat in them about the earliest cars.

The standards mention that the fitment of steel overflow tubes commenced after engine number 1551. That leaves approximately 1450 engines (engines started at #101) out of the 50,000 or so Frogeye 948s that did not have their overflow solution covered by the official concours standards. So what did the early cars use?

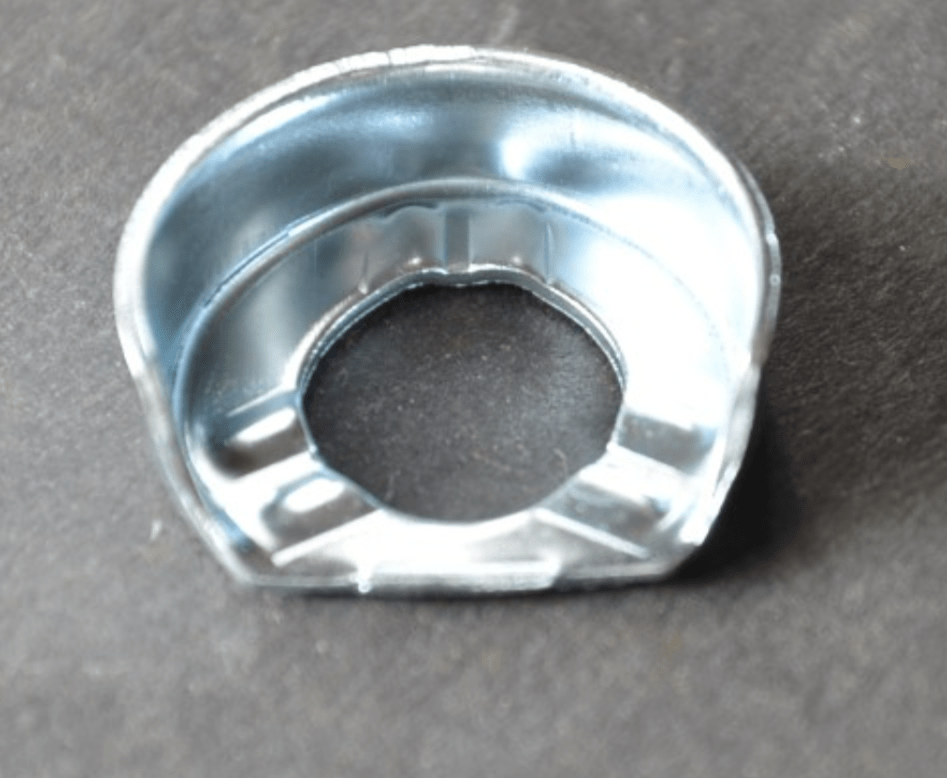

As it turns out, the very earliest Frogeyes left the factory with no overflow tubes installed at all. Instead, the carburetor float bowls were fitted with shorter top nuts and a special vented washer that allowed the bowls to vent. We believe that there was an issue with the earliest cars with sticky float bowl needles (as is sometimes a problem on SU carburetors) that caused excess fuel to pour out of the bowl, and with no tube to direct them, spilled all over the hot exhaust below, creating a potential fire hazard, necessitating a change to the steel tubes. You can see in the photos below how this early car arrangement looks in practice:

The trickiest part of the whole process in figuring out what vents were present was the research involved to prove that this was the setup used at the factory. After several hours of reading through every edition we could find of every service manual and parts list we could get our hands on, we finally found the documentation we were looking for. More on the documentation is in the video below, as well as how the vents work:

We have cracked the code on one of the most mysterious details, all as part of 501’s quest for gold! We find out its fate next Tuesday! Stay tuned!