Our latest project started as a bit of a nightmare… Imagine waiting seven months for your number one Frogeye to arrive and then completely filleting it on the floor of your garage. With just eight weeks to rebuild the car completely to concours specs, the voice in my head kept saying “what on earth are you thinking?” 501 showed up nicely restored but with disk brakes, HS2 (later) carbs, an electric fuel pump and lots and lots of incorrect hardware. It all had to go in our quest for concours gold.

August dawned this week with a lot of key concours point sucking issues behind us. We corrected foundation issues and started the rebuild and now this project has taken on an entirely new dimension.

It has become a lot of fun.

We’re in the homestretch for completion and while there are still dozens of minor bits that we need to work out for accuracy (and maximum points) we’ve overcome most of the large hurdles and set this thing right. Bugeye Sprite number one will be ready on September 18 for the national concours judges. Four judges will spend about two hours combing every inch of this car. Everything has to be correct AND it has to look nice. If we’ve built a beautiful re-creation of the way this car looked the day it left the factory (and score more than 950 points), then we win a gold award.

It’s a humbling project and it’s quite fascinating to me that we started building Bugeyes 15 years ago and we’re still learning new details each and every day. This project forces us back to our roots, and allows us to meticulously study of the foundation of everything we do. Only once we perfect exactly how it was done by the factory can we improvise and make it better. We are tasked with making every detail count, and while this car would not be the one you would chose for a cross-country Bugeye drive, it helps us make the next car modified for that job just that much better.

Most of our builds are drivability-focused upgraded Sprites. “Tink,” for example, is a Super Sprite we’re currently building for Don in Colorado, with a supercharger, five speed transmission and many other upgrades. Tink is built for Rocky Mountain passes and maximum fun in a wide range of weather while 501 will probably only drive a few hundred miles over the next 20 or so years. Customer needs rule. While Tink and 501 are both Bugeyes, it feels like we’re building two totally different beasts.

And yet, we are completely committed to being expert at both extremes. We have been much more focused on performance and reliability builds since the last gold level car we built… AN5L 552 was judged Gold in 2015, so it has been seven years since we focused on this kind of detailed and judged build and it is a gift to have the opportunity to revisit concours work now seven years later.

Concours judging includes a driving test. Your tachometer can’t waiver, or leak any fluids, all the lights need to work… everything has to work just like on Tink but the difference is that we’re building for drivability on one and accuracy on the other. Helmet covered battery terminals, for example, score us maximum points for accuracy in the concours and they will work perfectly during the judging but in terms of durability you would never want a helmet cover battery terminal on your car-they loosen up all the time- so these are simple examples of a much bigger challenge… how do you create something that’s perfect whether it’s perfectly accurate historically or perfectly drivable in the Rockies? These are the questions that move us to action and challenge us to be our best.

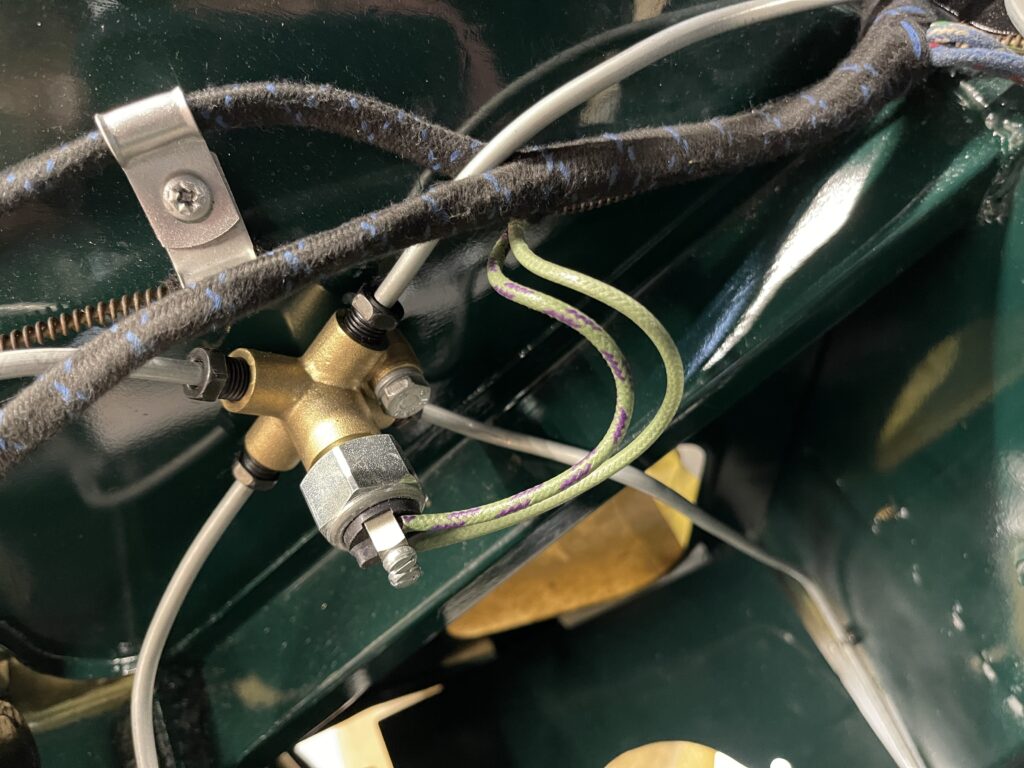

501 started with a leap off a cliff and the project has turned into a fantastic educational test to see how accurately we can make the colors and the textures and the materials so that this car looks just the way it would’ve looked in March 1958 when it left the factory floor. Some of my favorite concours details are are shown in the pictures throughout this post. This has been a lovely way to fall in love with a whole new facet of Bugeye building!