Nose jobs are a part of our daily routine.

Every Bugeye nose has been through the war and has been smashed in its own unique way. Bonnets don’t usually fit the way we might like, and so we have all sorts of tricks to try to get them back into shape so they look good on the front of your Sprite.

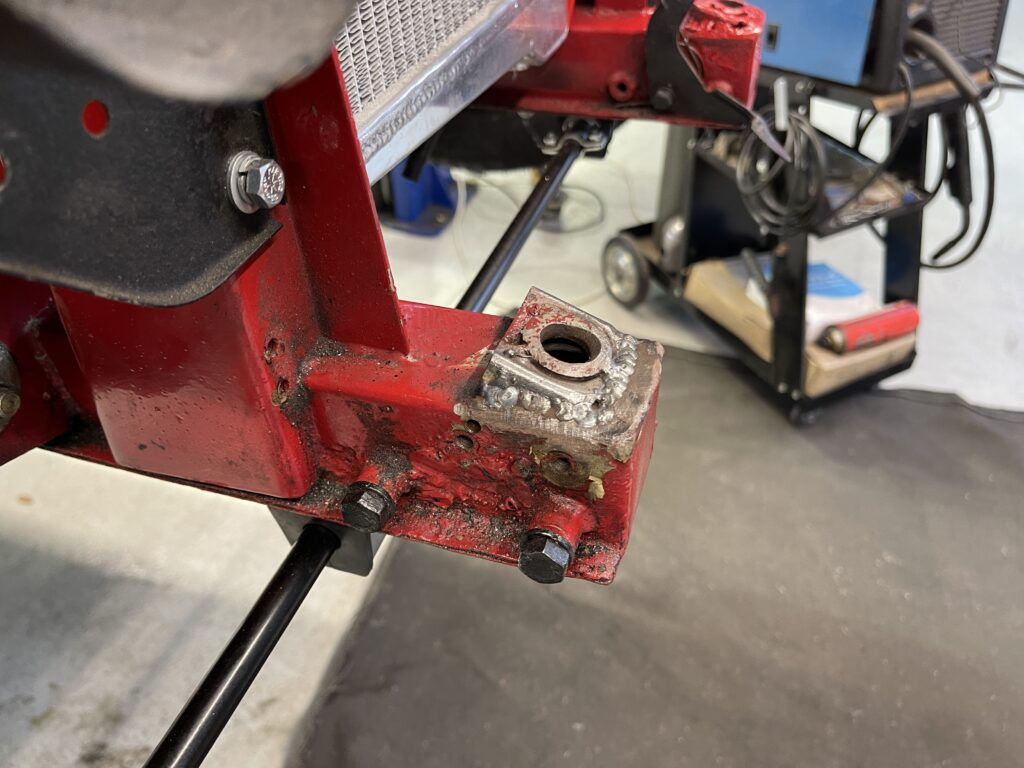

One of the drastic measures we sometimes need is to cut off the mounting receptacles that live on the front frame horns. This is often necessary when the bonnet “chin” (beneath the grill) gets pushed aft from a hit and the locking pins cannot be engaged in the receptacles on the frame horn. By moving the actual receptacle on the horn it’s sometimes much easier than to reshape the bottom of the front of the nose (and the resulting body and paint work).

And that’s exactly what we’ve done here for “Benji,” a car that we’re preparing for Steve in West Virginia. In this case, we sliced off the mounting flanges from the frame horns to move them aft just enough so that the cones on the nose could engage properly when the nose was lowered. This is a bit of a drastic measure, but it’s something that we often have to do to get these noses to open and close and lock properly, which is critical so that you have a nice parallel line at the “A”pillar, where the nose/wing meets the body of the car.

This is an advanced level exercise best left to a skilled body shop; or, should you send your car to us for sorting, it’s one of the things at our disposal if your nose need extra attention.

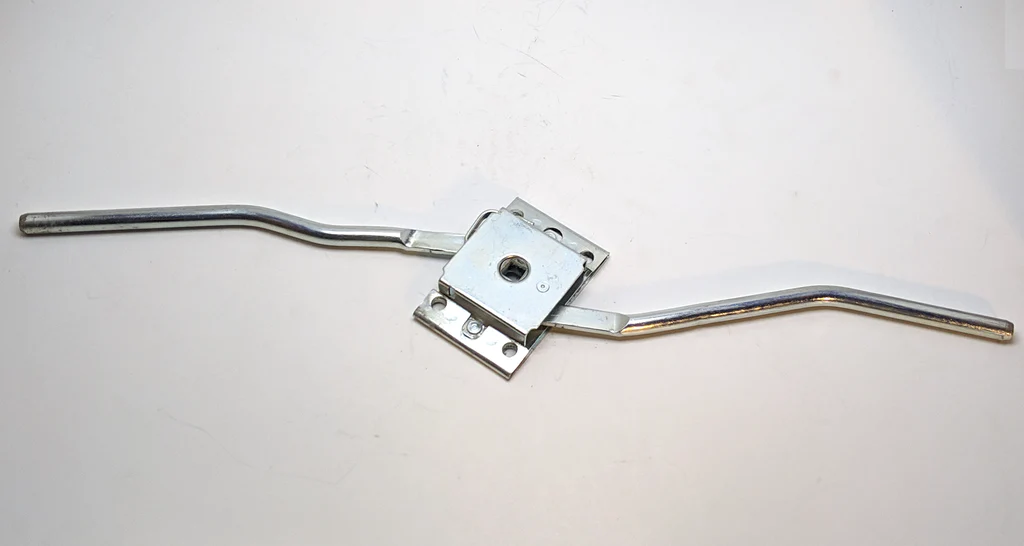

Make sure you have the right pieces in place… to fit your nose, you should have the cones, latch rods and latch plates. (We offer all three of these in our catalog, see the links above for more information.) Latches are often removed because noses routinely don’t fit as mentioned above. The latch helps reduce rattles. And heaven forbid you get into an accident, you’d like to have your nose properly latched so that it doesn’t leave the premises!