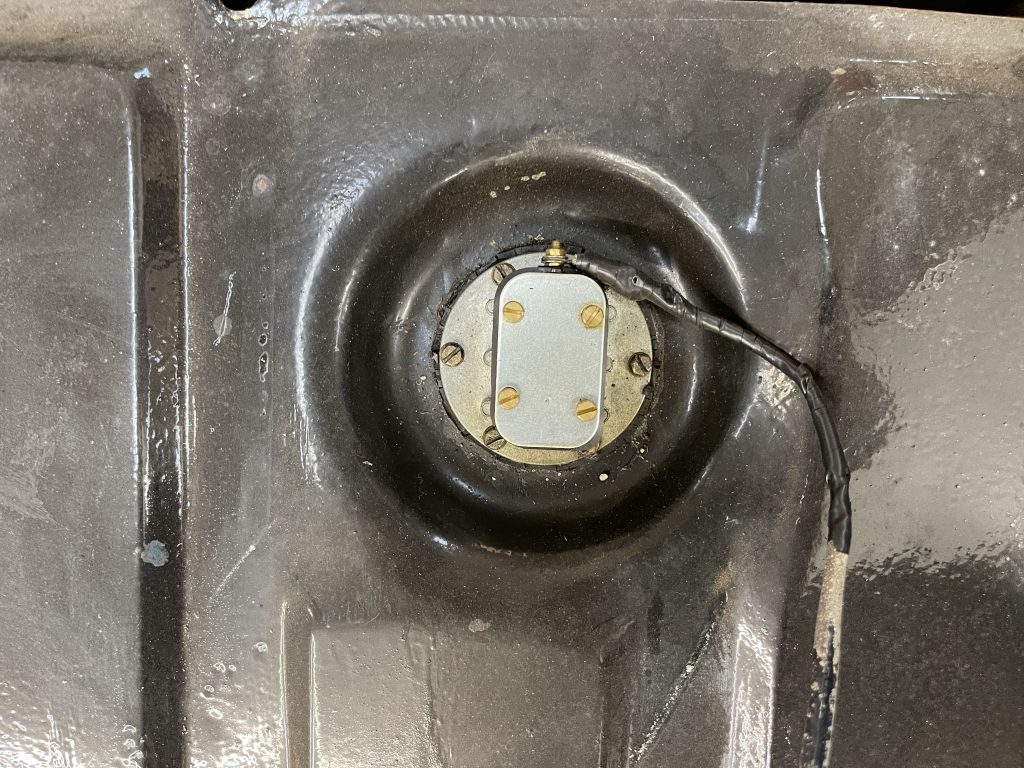

We’ve had many posts about Fuel sender’s, but it never ceases to amaze me there’s always a new way for people to mess this up so it’s worthy of one more post. The tank shown has the sender mounted 45° out of whack- and can’t move fully without hitting the tank. I didn’t think you could install a fuel sender this way – and the online auction where this car was purchased would not reveal this so the buyer had to have us fix it.

There’s actually a dent in the tank so that it can go all the way up to “full” the float has to go up to the top of the tank to send the needle up to full. Also interesting about this photo as you can see how much corrosion has happened from fuel leaking out of the top of the cork gasket. You can see the stains and the loss of paint indicating that this one would’ve been leaking badly. Of course the owner complained that the gas gauge didn’t work at all!

You want to float aligned, as you see in the other tank in the picture and you need to make sure the screws are sealed on the top with the correct washers. You’ll also want to make sure that Viton gasket is properly fit – if it isn’t, it will leak fuel when you fill it up. Before installation, make sure you pressure test the tank so you don’t go through the hassle of doing the job twice when you find out you have a fuel leak next time you fill-up (or if you prefer we sell a complete tank fully assembled and tested which you can purchase by clicking here).