With supply chain issues and pandemic closures, it sometimes feels like the world is broken right now. But we had a jump on everyone else… British classic car world was broken long before the pandemic arrived. Our day is spent with broken things, and our job is to figure out efficient ways to keep everything moving forward nonetheless.

Parts quality has been a challenge for a long time, and by specializing, we have found the various work-arounds to keep making our cars great. Each month, it seems we need more and more fixes, even for new parts.

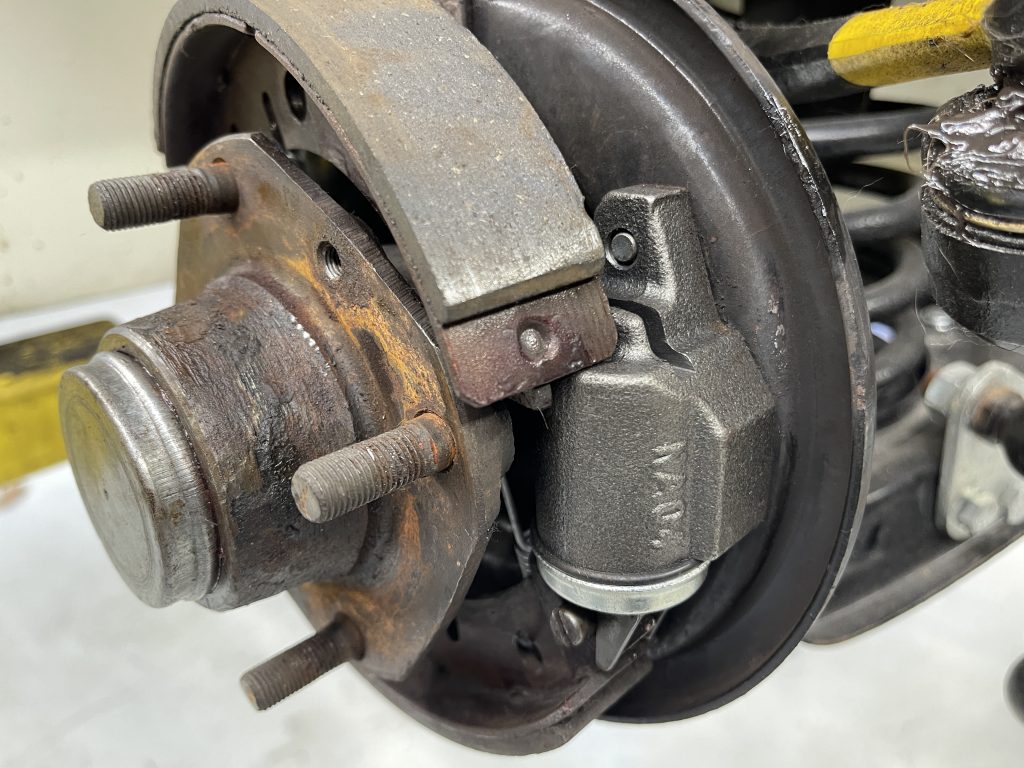

We had one issue this week that was new… the front brake cylinder we sell (which we have found to be the best for longevity) needed a minor modification on the casting to get the front brake shoes to line-up in the drum. This squared-off top of the cylinder needed to be rounded slightly or the front shoes would not properly seat in the drum, thus forcing the shoes out of alignment. It’s pretty simple to correct, if you know what to look for, so I wanted to make this post to help should you run into this in the field. This is an anomaly, we don’t expect that you need to do this, but in this particular case we needed to grind the casting in order to make everything fit. You can see the before and after in the photos shown.

Sadly, this is the current reality. You can’t run out and find a wheel cylinder that fits better… we’re already selling the best one available (we’ve tried them all). Because of low production numbers for all the parts on which we rely, there is often only a single supplier for the parts we need and trust.

Thus, we will continue to document here the various solutions for the problems we encounter in our builds, and we will continue to edit and improve our parts catalog and fill it with the best parts we can find and test on the cars we build. With the right attitude, these new part modifications become part of the fun!