We heard about a Bugeye front stub axle break this week, which resulted in the wheel departing the vehicle. Fortunately, this happened in the owner’s driveway and with minimal damage. With the help of a furniture dolly under the frame, he was able to roll the car into his flat garage and from there, he can have a flat bed take the car to be repaired.

This failure looks very dramatic, but this is a VERY rare occurrence. To put this in perspective, after nearly 15 years and more than 300 cars we have never seen this happen before. So I wouldn’t worry about this potential failure. But you would be smart to know about this potential issue, and you should work to minimize any risk.

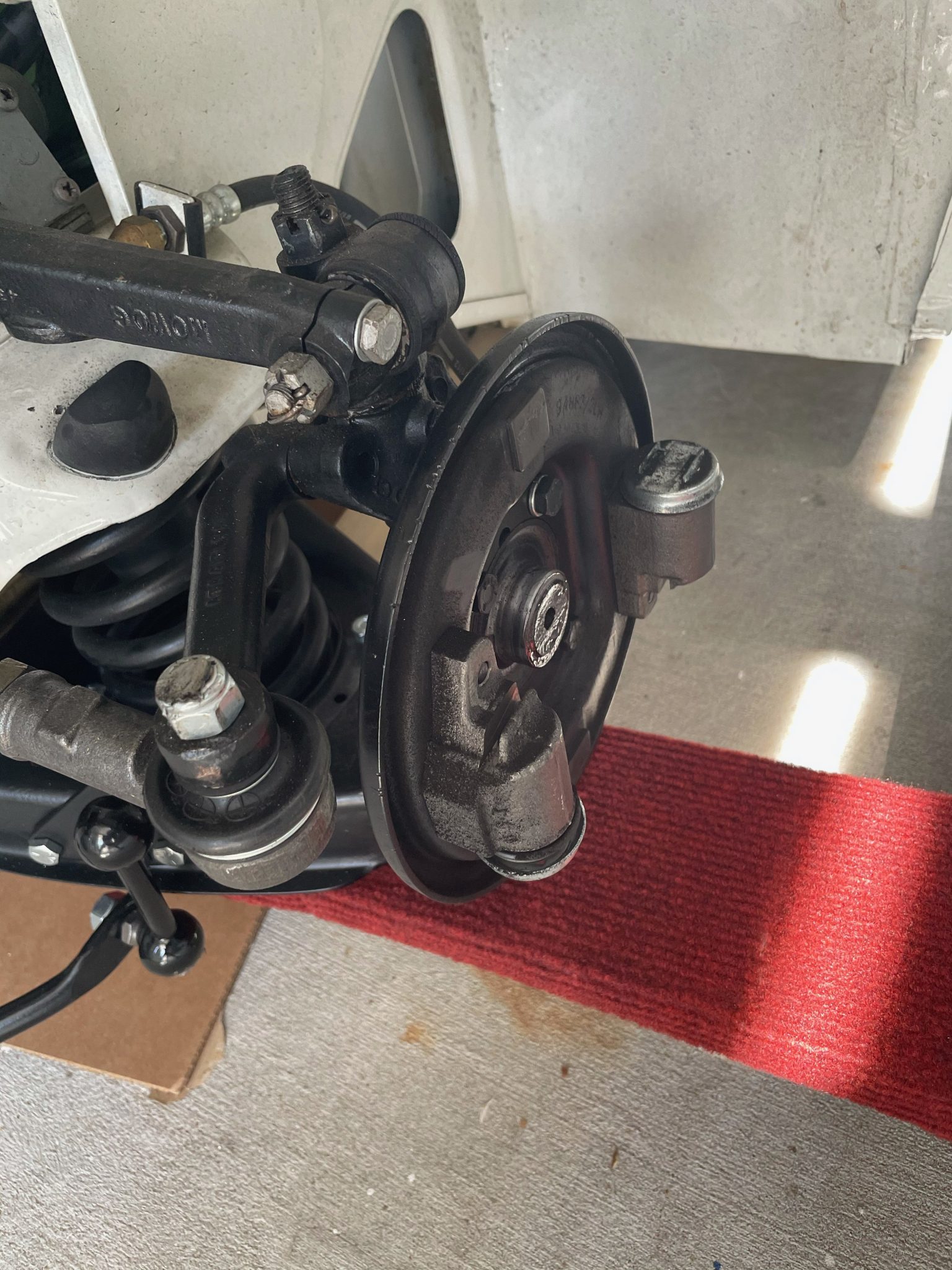

This drum brake front stub axle was installed in 1960. In the 61 years since installation, who knows how it has been hammered and/or abused. Certainly, it has seen its share of ups and downs. And if this car was raced at some point in its lifetime, a lateral hit at the track, for example, may have stressed this swivel axle a long time ago. If a small crack happened back in the days when television only really existed on three major networks, it may have taken this long to manifest as a failure.

We’ll never know.

Here’s how you can address this small risk:

1. Make sure your shocks are working properly. They don’t call them dampers for nothing. If you hit pot holes with non functioning front shocks, more energy will be transmitted to the front suspension components. About 50 percent of the cars we see have worn or blown front shocks. The front Lemans shocks we sell seem to last longest.

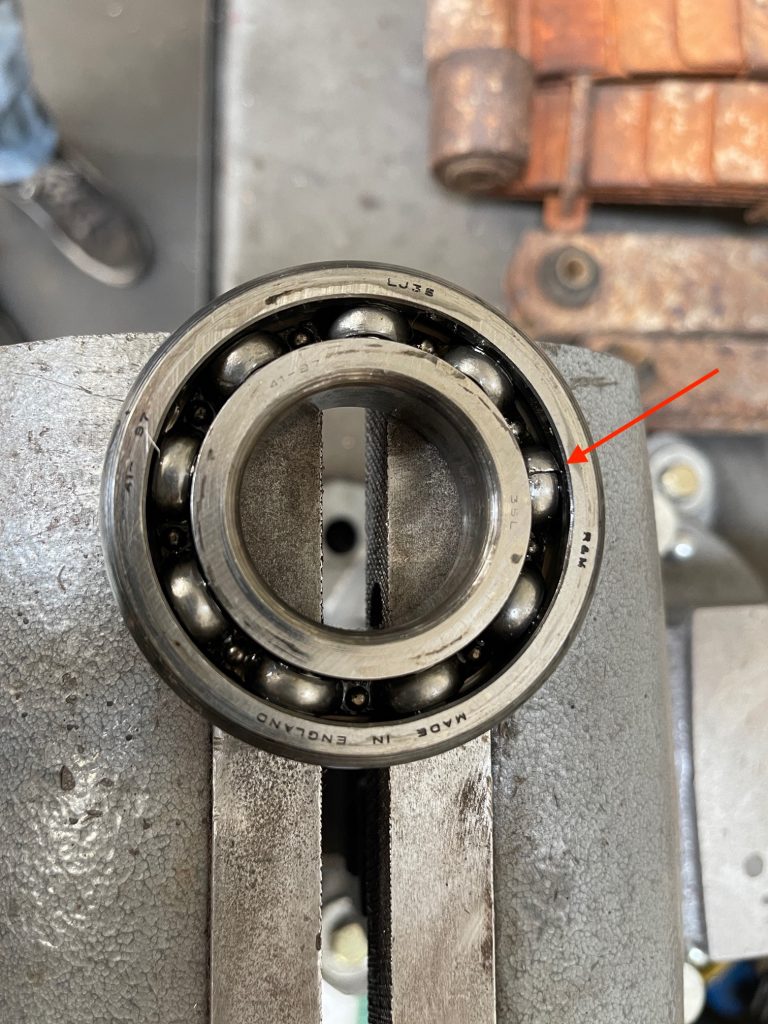

2. Upgrade to tapered front wheel bearings. When you remove the hub and original bearings, check the stub axles visually for cracks, especially where the horizontal and vertical meet. The original ball bearing front wheel bearings are an outdated design and these too need to be inspected if you are not going to replace them. You can see in the photo below an original caged front bearing with a cracked ball in the cage over the bearing. All cars should be upgraded to the more modern wheel bearing design, which you can purchase by clicking here.

3. If you are building a car with used swivel axles, make sure to have them magnifluxed before assembly, this is the best way to detect cracks. Or upgrade your front end to disk brakes and start with brand new disk swivel axles. This may be the best way to reduce risk of failure. Start with new steel and disk brakes are a bonus you’ll get for the changeover. New swivel axles are not available for drum brake set-ups so if you want new stub axles, disk is all that is available.

The car with the failure above is a car we didn’t build or sell so we don’t know much about its history. It is a great restored car that we serviced, but we didn’t work on the components that failed and we don’t remove the front hubs unless we are upgrading to tapered wheel bearings. Even still, we’ll never know if this car had a visible crack prior to the failure. We expect to be doing more disk brake conversions with new parts in the coming years, to do what we can to minimize this risk.