It would appear that the parts used on the front suspension of this particular Bugeye were once stored in a bucket of rainwater. I can think of no other explanation for the massive amount of pitting we found this week while repairing a set of worn kingpins. Many Spridgets have worn kingpins but we have never seen them as pitted as these.

This is a nice car, with lots of new parts present. The new owner chose to have us replace the king pins because of the play we detected in the front wheels. You can see the bushing wear evident in the video below… the wheel is not supposed to move in and out as shown. All this is due to wear of the lower king pin bushing (and is not reccomended if you want precise steering and handling).

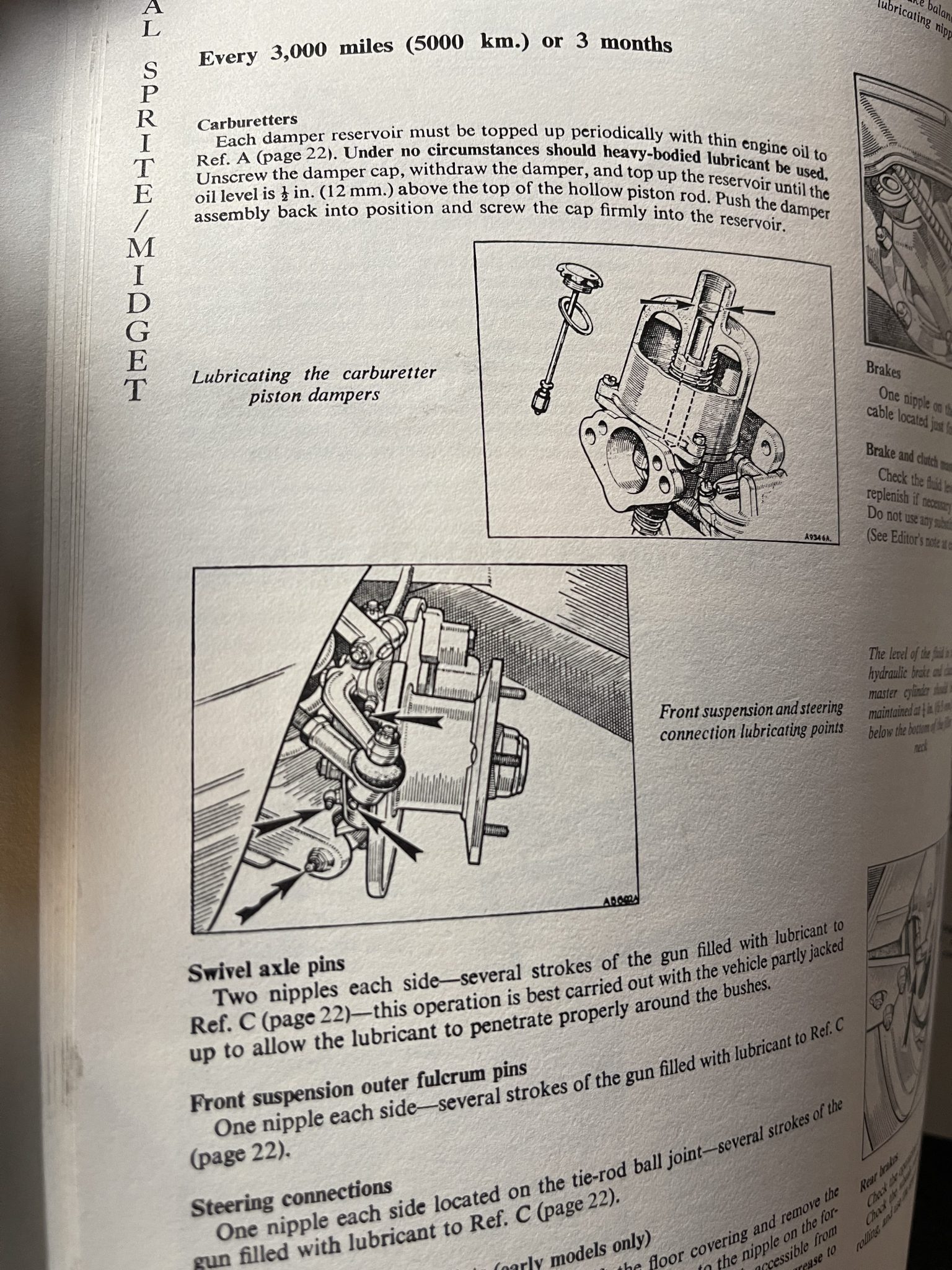

Such wear is common, partly because of the design and partly because people do not heed the recommended 3000 mile interval for greasing these bushings. As our fleet ages, maintenance (and quality repair) is more important than ever. As shown below, you can see that liberal greasing has been recommended by the factory since day one.

Anyway, these pockmarked surfaces above have been abrading and grinding-off whatever is left of the brass swivel axle bushings with every turn. They had been well-greased recently, but it was far too late to matter in this case.

Moisture has once again played a starring role in our blog posts. In your fuel, your oil and now your swivel axles, moisture is still the enemy. Was this car stored in a really damp garage? More likely, back before it mattered, someone needed new king pins and found a pair at a junk yard in a bucket full of water, cleaned them up and hoped for the best, just like we all did before the invention of air bags and Twitter accounts. And now, umpteen years later, this is what has been driving around holding-up the front end of this Bugeye Sprite.

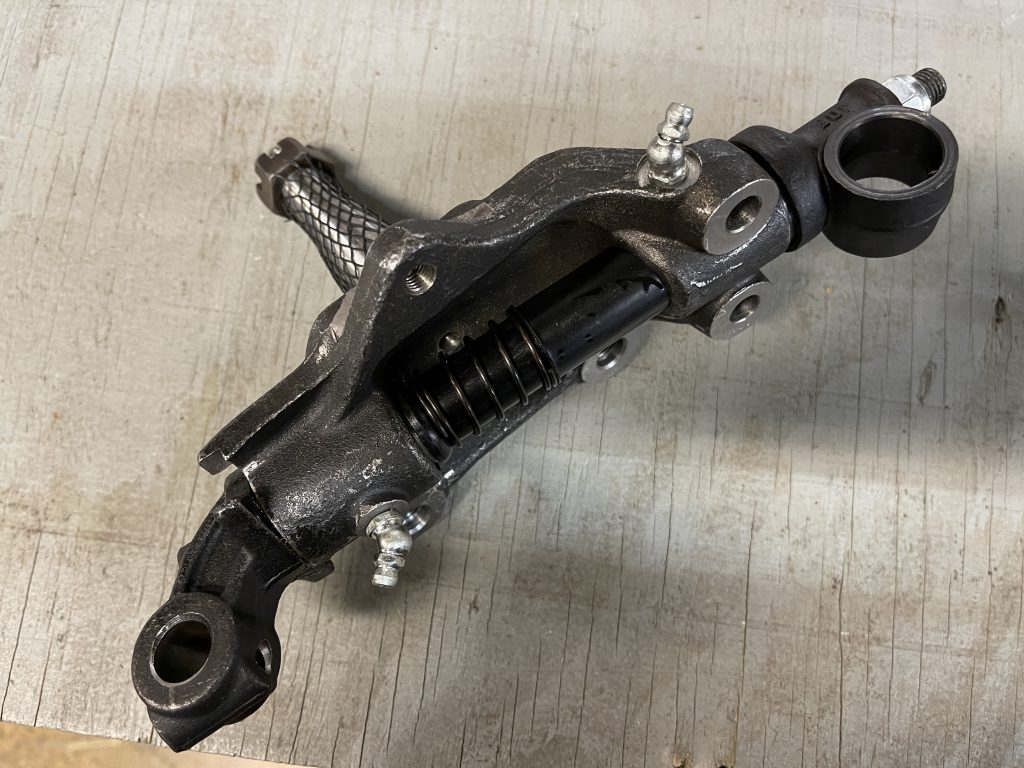

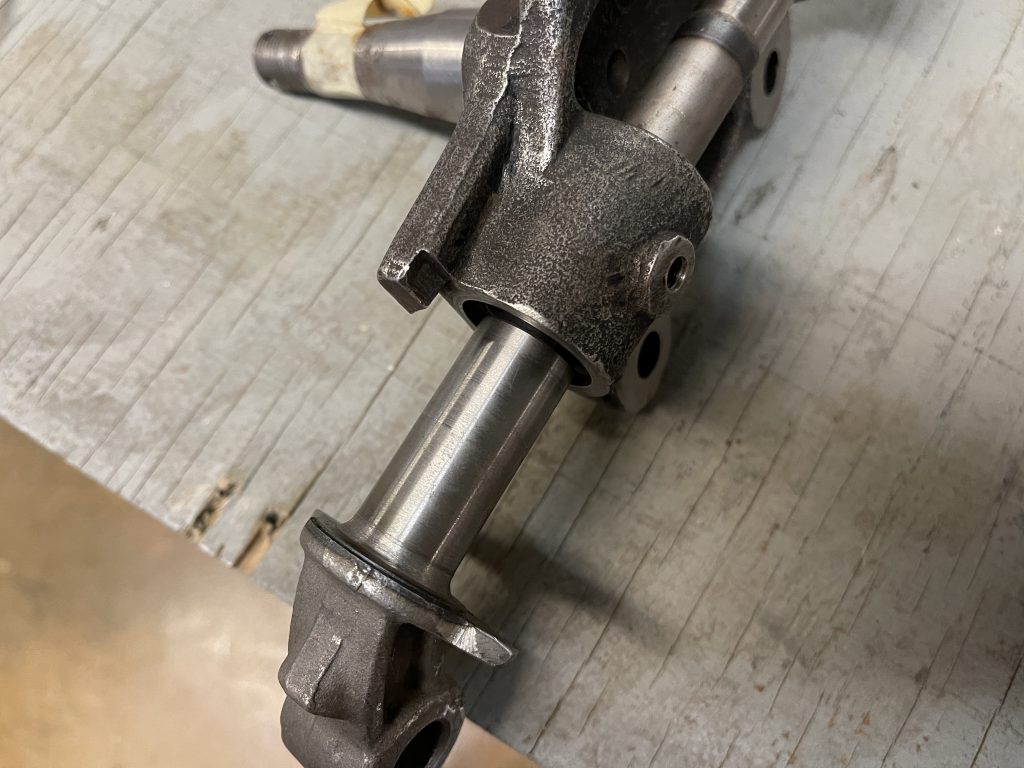

The good news is that we have all the parts to make this right, as long as you have a disk brake equipped car (and if have a drum brake car with worn king pins that you want to fix, these parts shown are integral to a disk brake conversion, which you can purchase by clicking here). We sell complete swivel axle assemblies with new bushings pressed-in and properly reamed to fit correctly. This makes it easy to swap the entire assembly. Above, you can see the new nice smooth bushings and new king pin, temporarily removed from a complete assembly like the one shown below.

Note the grease fittings shown on the new assembly above. The left fitting in the photo greases the lower bushings, and the right fitting lubricates the top one.

Above, you can see a new king pin. It has been lowered out of the swivel axle so you can see the nice new bearing surface for the lower bushing. So please heed the shop manual and head right out to your car and squirt some grease into your swivel axles for the new year.

Your bushings will thank you.

Buy new complete swivel axles by clicking here. If you are planning to use your old swivel axle, but would like to replace your bushings and king pins, click here for a major suspension rebuild kit. And feel free to call our parts department during business hours if you have questions about how to best restore your front end.