At times this week felt a bit precarious, as we pushed to produce our next crop of great cars, electric or otherwise.

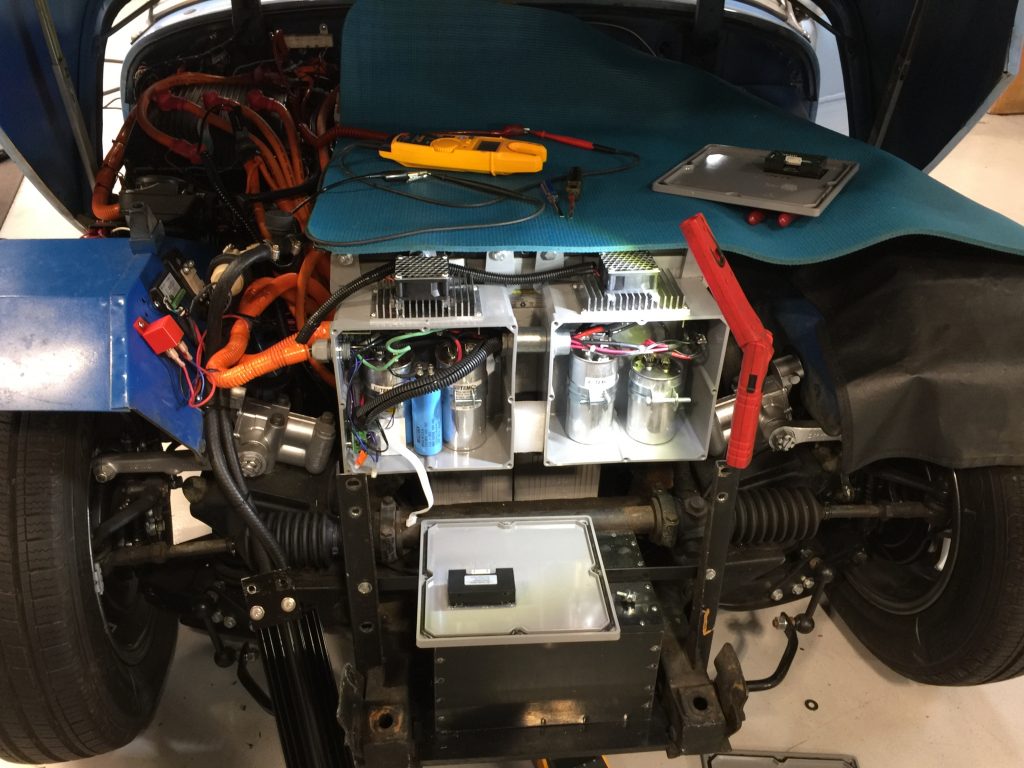

This week we put the new charger in our latest electric Bugeye. This one puts almost twice as much juice in the battery pack as the prior iteration. The quest to improve charge time for our customers had us take out a perfectly good 2KW charger for the new 4KW model shown below. This means each hour of charge time produces twice the range.

Soon, we’ll send this blue car out into the wilds of Maryland, where we are sure that faster charge times will be appreciated. There’s just a little more wiring to complete first.

Also this week we watched the slightly precarious transport of one of the fiberglass Bugeye noses (from our parts catalog) on the roof of Andrew’s FJ. It made it safely to his shop, where it will be graced with ample primer and paint, so that another (gas-powered) Bugeye can come back to life.

This week, we also said goodby to our stunning 1967 AH 3000, which is currently on the way to BC, Canada and then on to New Zealand for a month-long rally in February, 2020.

Before departure, we were tasked with protecting the oil sump and exhaust from impact with rocks or hazards on rough roads on the rally, so Kenny fabricated the impressive skid plate (above), as well as a trick exhaust guard which is drilled with holes to match the custom wheels already on the car.

These plates should save the underside of the car on rough terrain. I was delighted with the way the exhaust gaurd looks in profile, since it looks like it was there from the start, with the alternating holes just like the ones drilled in the wheels. We also raised the car a few inches to improve ground clearance.

After an action-packed week, I look forward to some quiet time this weekend, perhaps watching the grass grow (but it always seems to come back to Bugeyes).