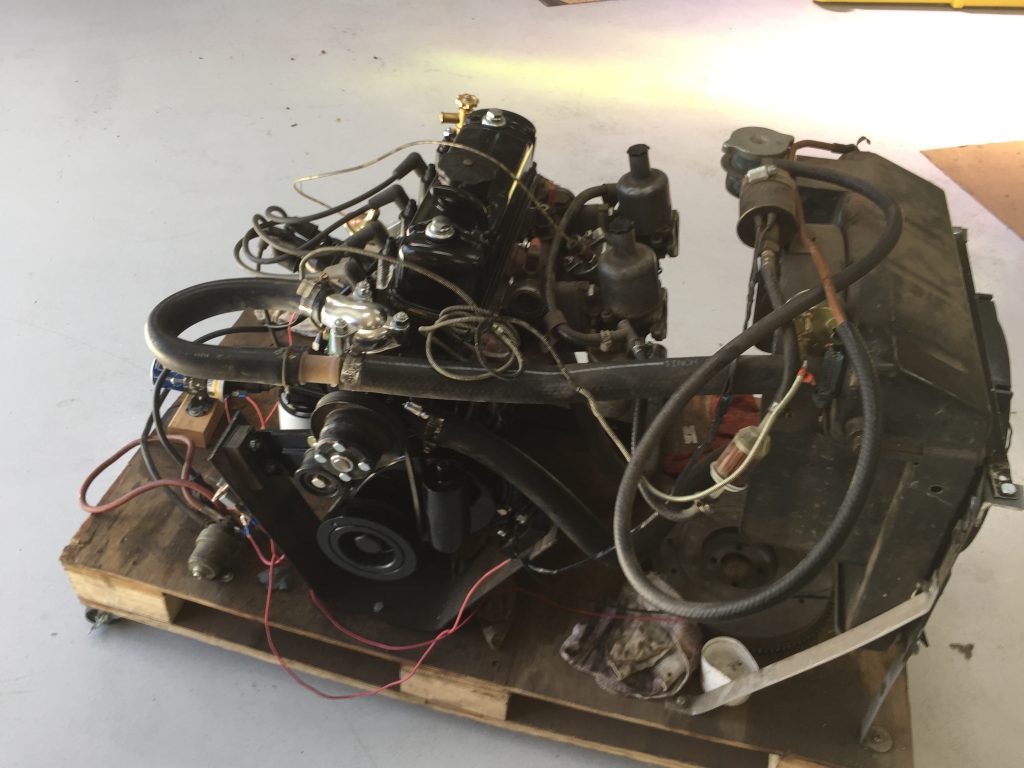

Way back when, we would buy engines and drop them right into the car. Too often, we would have an issue that would have been much easier to repair when the engine was out of the car. So we built a simple bench test stand, and now every new engine gets a work-out and camshaft break-in before we put it into the car.

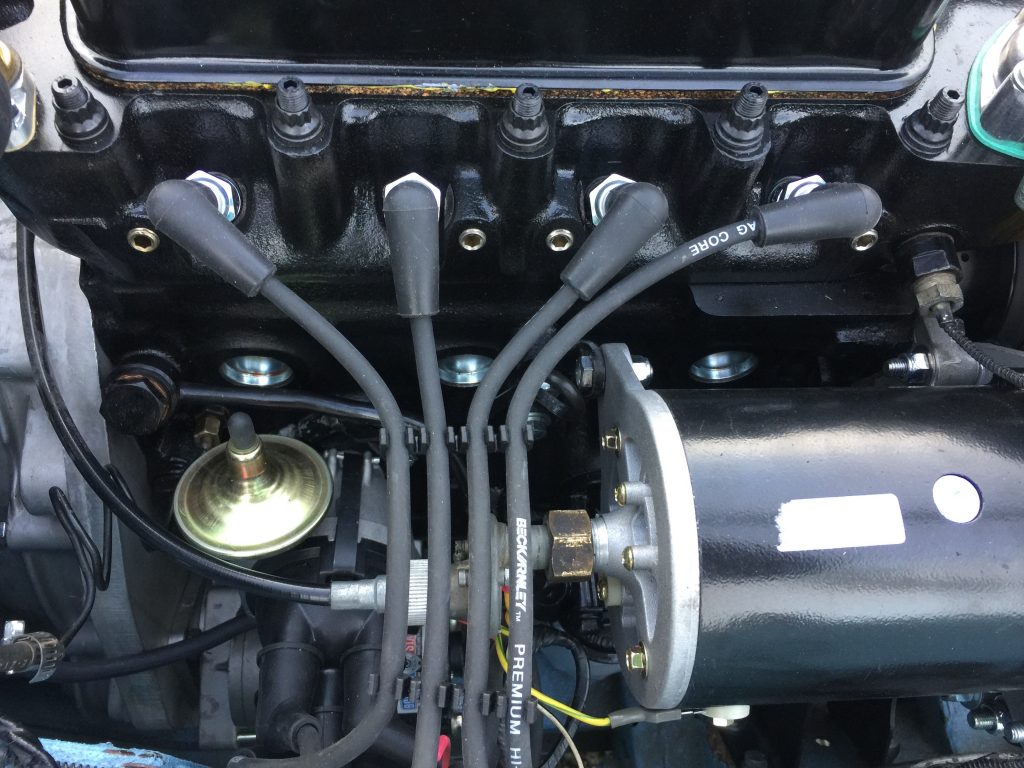

This week, we received a rebuilt 1275 engine from a client, and when we bench ran it, coolant started leaking from the core plugs. You can see why they leaked in the photo below… there was quite a bit of corrosion around the perimeter of each plug. We cleaned out the block and pressed-in new plugs, which fixed the leaks.

The front main seal also leaked, which we centered and re-sealed. And the timing cover breather was pushed aft in transit which caused chafe between the timing chain and cover, which made quite a noise. With all three issues fixed, this engine was now good to go. Now we can put it in the car.

Bench running is a good thing.