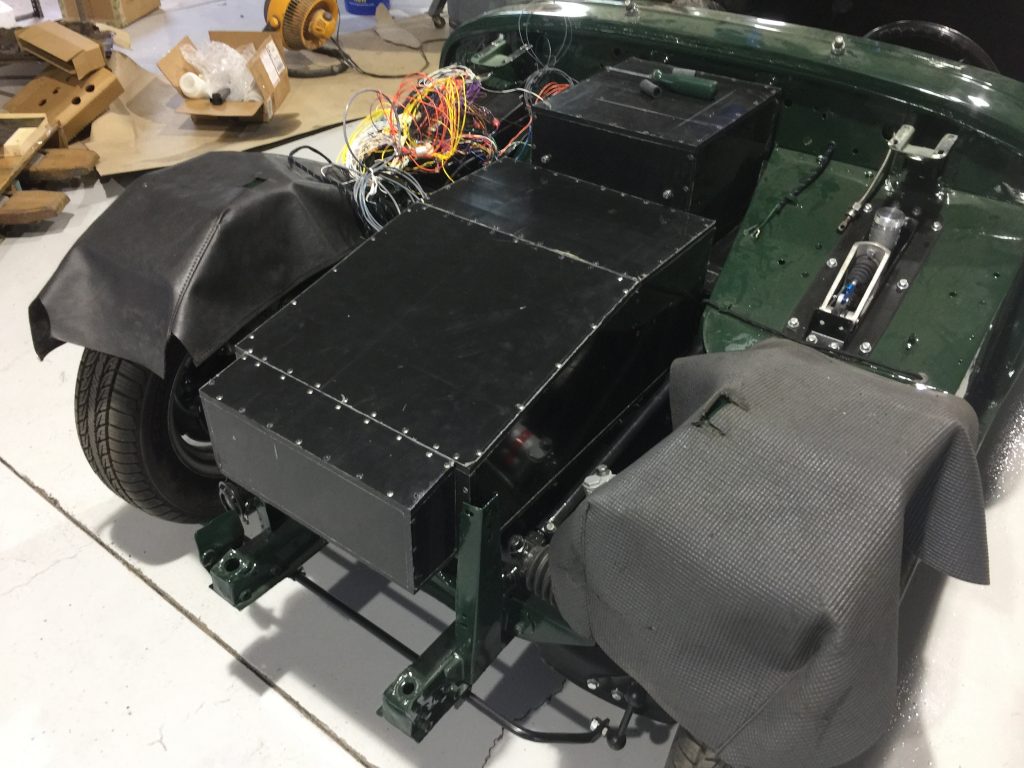

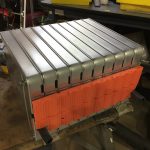

The electric Bugeye Sprite (FrogE) is leaping forward. This week we made big strides with the creation of the polyethylene boxes to isolate and protect the precious Lithium Manganese batteries. Each one is in its own little safe. Kenny fabricated beautiful boxes this week to house each set of cells. In the photo album below, you can see the boxes going together to fill the engine bay with new (cleaner) power. Is it cold and plastic under the hood or hot stuff?

This week we also mounted our new custom drive shaft, which you can see below linked to the electric motor. This photo shows how neatly the team linked the electric motor spindle to the drive shaft. In this image you are looking down through the shift tower at the connection between motor and drive shaft.

Some electric conversions use the existing gearbox but we went with a direct drive configuration, to eliminate one more source of oil leaks. These cars are so light and the performance envelope for the motor is so broad that a gearbox is not needed. Losing the gearbox also saved us about 46 pounds and allowed is to mount the motor closer to the center of the car, down low.

The car has a 12 volt system for the lights, horn and accessories. This is charged through the main plug in the fuel tank through an inverter. The main motor batteries (inside the black boxes) are 144 volts and 500 amps.

Our goal is to have this complete in one week in time for British By the Sea in New London, CT. Will we make it? (Now, where does that white wire go?)