“Gumby” is coming together nicely. We are pushing to have the car ready to debut at the British by the Sea car show this coming June 4, in Waterford, Connecticut. At left, you can see the car secured to the dyno, as we finalize the tuning of the custom multi-port fuel injection system.

“Gumby” is coming together nicely. We are pushing to have the car ready to debut at the British by the Sea car show this coming June 4, in Waterford, Connecticut. At left, you can see the car secured to the dyno, as we finalize the tuning of the custom multi-port fuel injection system.

Performance wasn’t the only goal though, and with the resurrection of the Bugeye I purchased in high school, we set out to push the envelope and create the ultimate interior while echoing the original flavor and design. Our goal was to pay sufficient tribute to the heritage of the car, while adding elegance and style. We chose to add custom stitching throughout the interior, to upgrade the entire interior without going too far afield.

< It all started with a single cowhide, custom dyed in a dusty light green called “aloe thorn,” and embossed for additional texture. This is the custom color we chose to coordinate with the Aston Martin green and Mercedes silver paint that adorns the sheet metal on the car.

It all started with a single cowhide, custom dyed in a dusty light green called “aloe thorn,” and embossed for additional texture. This is the custom color we chose to coordinate with the Aston Martin green and Mercedes silver paint that adorns the sheet metal on the car.

Here, Kenny maps out the components of the interior on the uncut leather, careful to ensure maximum yield.

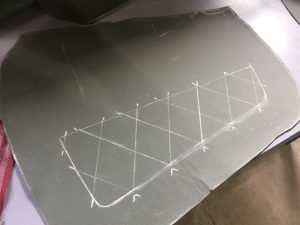

Next Ken diagrammed the diamond designs we created, careful to ensure the the pattern was symmetrical and balanced. Here, you can see his design for the custom door pockets, which use the original components but accentuate the factory recesses with diamond stitching.

Next Ken diagrammed the diamond designs we created, careful to ensure the the pattern was symmetrical and balanced. Here, you can see his design for the custom door pockets, which use the original components but accentuate the factory recesses with diamond stitching.

In this image, Kenny sews the contrasting stitching on the seat base to add detail. We were tempted to keep the original ribs normally seen on stock Bugeye seats. We considered adding diamond stitching to just a few of the ribs so that we retained more of the original look. But in the end, we chose to make the entire usually-ribbed center section into a diamond design. (Note, this is the same leather, only the lighting is different, so the color appears darker)

Ken made certain the diamond patterns would align once the seat bases and seat backs were united in their frames. Here, he carefully checks the patterns before he starts sewing. Next, you can see the seat backs completed, and laid out with the leather for the seat bases. Next, Ken made custom silver metallic piping, to match the stripes down the center of the car. Then he stretched the leather over new foam pieces, and with some additional tailoring, the covers and seats were complete and ready for installation.

The door pockets went in next, and then Kenny created custom green check straps to match the leather in the car, stitched with the same contrasting thread detail you would find on stock check straps. He then sewed a high grade German wool heel pad into the rubberized floor covering in the driver side footwell. He next affixed matching green panels onto the vertical surfaces of the car.

Below, the interior is nearly complete, after a good 50 hours of custom work above and beyond the normal time it takes to build an interior. The outstanding result is fitting for the car that inspired the creation of bugeyeguy.com, and a beautiful acknowledgement of the now 204 Bugeyes that we would not have sold were it not for the inspiration Gumby gave us.

In 1979, I purchased this car for $1,100. It was dented and dinged, finished in primer gray. There were no floor coverings and the seats were covered in glossy metallic teal vinyl. The car was wired with lamp cord and the dashboard was perforated with multiple additional holes. Now, after ten years sitting un-restored in the Bugeyeguy warehouse, Gumby is back, with one of the nicest interiors in the Bugeye world. And this custom interior is merely the starting point for future custom interiors we build into “Super Sprites” in the years to come.

Many thanks to Ken Bugden for patiently executing this vision, and for bringing this sculptural interior to life.